-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Plumbing a valve

- Thread starter solo

- Start date

- Joined

- Oct 15, 2013

- Messages

- 300

It is pretty much standard to have a top and a side port for both the inlet (P) and the outlet (T).

With a joystick on there, you almost certainly have a two spool valve. As such there is an A and B work port for each spool (sometimes labeled A, B, C & D), four work ports. Thus two spools = two functions.

As above, is there a schematic supplied with that valve? It's a Salami, but what is the p/n of it?

With a joystick on there, you almost certainly have a two spool valve. As such there is an A and B work port for each spool (sometimes labeled A, B, C & D), four work ports. Thus two spools = two functions.

As above, is there a schematic supplied with that valve? It's a Salami, but what is the p/n of it?

- Joined

- Oct 15, 2013

- Messages

- 300

this thread picture explains the setup of hoses.

www.tractorbynet.com

www.tractorbynet.com

Daisy Chaining Loader Valves

I bought a second loader valve for my tractor to operate the top and float on the 3-Pt. I have the mounting and hydraulic connections figured out, pretty much just follow thee picture from the Summit Site The only question I have, is: Can I run the tank line on the first valve into one of...

- Joined

- Mar 23, 2013

- Messages

- 150

Thanks guys for all the reply's, I've been busy getting the new shop together. We sold a property, I hauled gravel, lumber.

It seems like a dozen things going on at once...I thought getting older was suppose to be slowing down. Fat chance here..

I believe I have it plumbed correctly. Since this is only for a grapple on my skid steer, I'm only using one spool.

I'll get a picture tomorrow.

It seems like a dozen things going on at once...I thought getting older was suppose to be slowing down. Fat chance here..

I believe I have it plumbed correctly. Since this is only for a grapple on my skid steer, I'm only using one spool.

I'll get a picture tomorrow.

- Joined

- Mar 23, 2013

- Messages

- 150

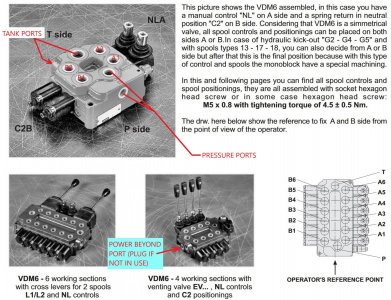

If I'm understanding correctly. I can use a power beyond Valve and not use a solenoid to control

The third function.

Top right, I have air line connected (pressure)

On the valve with the open fitting is going to the tank.

The fitting below the tank return, would be where the power beyond valve would go.

Putting pressure back to the other controls.

In a nut shell, using a power beyond valve, I will have all functions, working together.

And If, I would find a use for the other spool, I'm all good to go!

The third function.

Top right, I have air line connected (pressure)

On the valve with the open fitting is going to the tank.

The fitting below the tank return, would be where the power beyond valve would go.

Putting pressure back to the other controls.

In a nut shell, using a power beyond valve, I will have all functions, working together.

And If, I would find a use for the other spool, I'm all good to go!

Attachments

Last edited:

- Joined

- Oct 15, 2013

- Messages

- 300

Normally, when both spools are in neutral position, oil flow is from the inlet port across the valve to the tank port and returns to reservoir. With a power beyond option installed, when both spools are in neutral, oil flow is from inlet port to the power beyond port where it can be directed at high pressure to a downstream valve or function. When one or both of the spools in the first valve are shifted, the power beyond flow is stopped.

You still need to have a tank line connected to the valve when power beyond is installed.

If there is no downstream valve/function in your circuit you don't want power beyond installed.

You still need to have a tank line connected to the valve when power beyond is installed.

If there is no downstream valve/function in your circuit you don't want power beyond installed.

- Joined

- Mar 23, 2013

- Messages

- 150

This is for a grapple on a mini skid steer, it has a T handle set up, Right T controls the bucket, left T controls forward and backward/ turning.Normally, when both spools are in neutral position, oil flow is from the inlet port across the valve to the tank port and returns to reservoir. With a power beyond option installed, when both spools are in neutral, oil flow is from inlet port to the power beyond port where it can be directed at high pressure to a downstream valve or function. When one or both of the spools in the first valve are shifted, the power beyond flow is stopped.

You still need to have a tank line connected to the valve when power beyond is installed.

If there is no downstream valve/function in your circuit you don't want power beyond installed.

The power beyond will eliminate some hoses, and a bit simpler too. I got it now !

Thank you, I'll get back out there and make a mounting bracket and get things moving!