- Joined

- Dec 29, 2017

- Messages

- 60

I got the call this morning from UPS (or rather, the local delivery office for them that does the freight deliveries) and they said the truck would be here tomorrow.

Turns out it showed up today instead! I'm honestly OK with that!

Here it is, coming off the truck and the guy's pallet jack which got stuck in the gravel...I offered to put down some plywood, but he indicated that he didn't need it. So, it got stuck in the gravel, I had to prop it up with a couple of chunks of wood to get his pallet jack out from underneath, and then he buggered off after I signed my life away.

This is $4200 in some small looking boxes.

Got things re-arranged, hand-bombed the base into the garage, and then hoisted this big box into the garage. Brought the lawn tractor/snow-blower back in, and then started unpacking a bit.

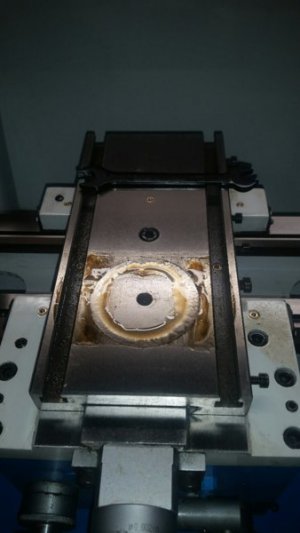

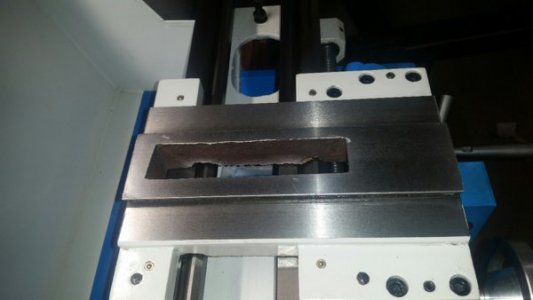

Yup. Looks like a lathe to me. Looks like there's no damage from shipping either, which is a good thing. There were a couple of scratch marks on one of the base cabinets, so it looks like it got a little bit dinged up, but the door opens smoothly, and it's only a bit of paint. not a big deal - it'll be hidden once the chip tray goes on anyhow. I got my middle minion to help me with this as well.

Here we go with the crate off, things unpacked and having a look at things. I am quite pleased with what I see. I packed it in early tonight...I'm going to be up early for work in the morning, but my garage has officially gotten busy again.

Turns out it showed up today instead! I'm honestly OK with that!

Here it is, coming off the truck and the guy's pallet jack which got stuck in the gravel...I offered to put down some plywood, but he indicated that he didn't need it. So, it got stuck in the gravel, I had to prop it up with a couple of chunks of wood to get his pallet jack out from underneath, and then he buggered off after I signed my life away.

This is $4200 in some small looking boxes.

Got things re-arranged, hand-bombed the base into the garage, and then hoisted this big box into the garage. Brought the lawn tractor/snow-blower back in, and then started unpacking a bit.

Yup. Looks like a lathe to me. Looks like there's no damage from shipping either, which is a good thing. There were a couple of scratch marks on one of the base cabinets, so it looks like it got a little bit dinged up, but the door opens smoothly, and it's only a bit of paint. not a big deal - it'll be hidden once the chip tray goes on anyhow. I got my middle minion to help me with this as well.

Here we go with the crate off, things unpacked and having a look at things. I am quite pleased with what I see. I packed it in early tonight...I'm going to be up early for work in the morning, but my garage has officially gotten busy again.