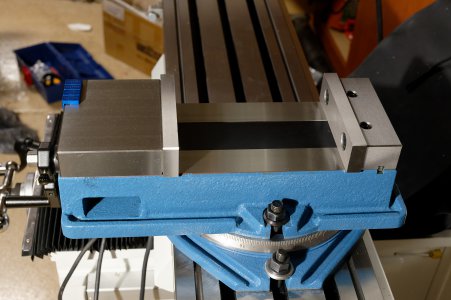

A little about the machinist vise. Of course I thought about Kurt. The standard. Saw the Homge Ultra Precision (the 6" Super-Open 8" officially). For the $399 and free shipping with the Mill I figured I'd give it a try. Also figured I'd likely end mill it by mistake and better the Kurt knock-off than a real one. Some observations (after some YouTube reviews of other, cheaper knock-offs).

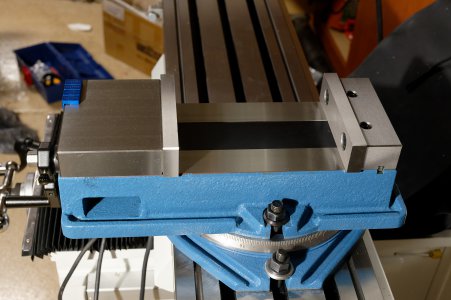

The casting is okay but certainly not as well finished as a Kurt. If you look closely we have some paint chipping off but a solid layer of primer underneath (a look inside a Taiwan mill shows the same). Aesthetics are okay. The surface grinding is really excellent though. Ground throughout (some of the cheapees leave the bottom of the jaw un-ground). This has the machined jaw hold-down button like a Kurt. Nice chamfered corners all around. Needle bearings in the leadscrew. Speaking of damage, dropped a wrench onto it Monday while loosening the draw bar (I need to get the power draw bar installed - I have zero muscle memory for this). Ended up bulging the jaw face. Crap! At least it wasn't a Kurt right? Found a local 54-years experienced master machinist down the road. Did a proper surface grind on it. I paid him with a hand shake and a shop tour (his shop). Awesome dude...probably not a Practical Machinist subscriber. Back in business.

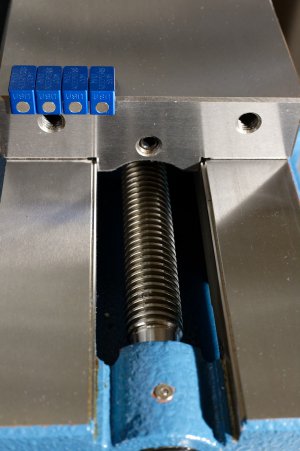

Has a steel cover to keep chips out of the threads. Nice touch.

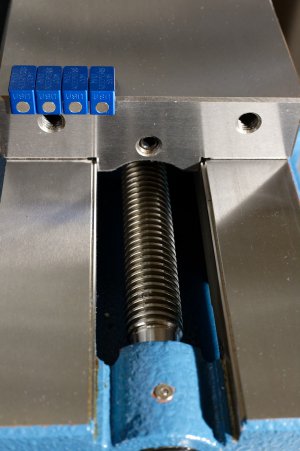

Very very nice ACME threads with backlash adjustment. This is a very nicely made piece. Smooth as glass. This is where some of the cheap knock-offs go cheap (v-threads and the like).

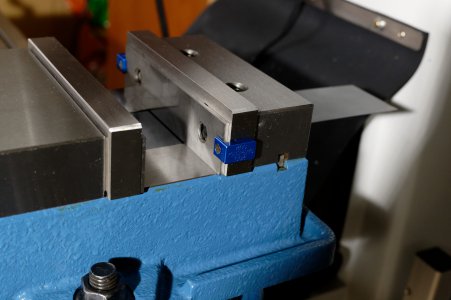

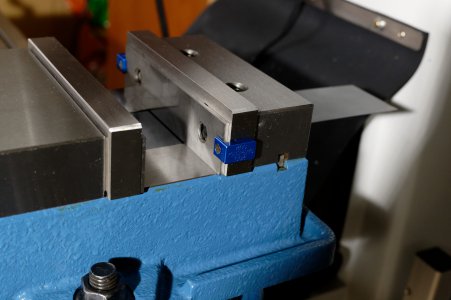

I really wanted to use the base (I'm likely in the minority). The nuts included in my PM supplied clamping kit were too narrow to clamp the base. At all really. Lame flat washers from Home Depot were a non-starter. What to do? We did some design and my kid 3-D printed some prototype shoulder washers to keep those 1/2" studs centered and stable.

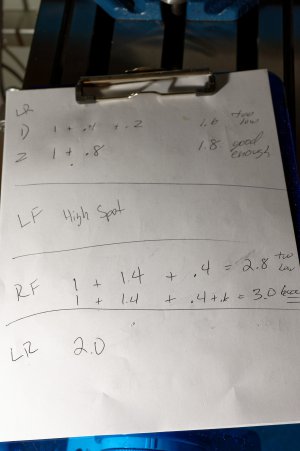

Fabbed up the washers and the vise is super solid. Just enough wiggle room to get this thing to index really nicely. Very accurate vise. Comes with an inspection sheet and I believe it.

Also wanted to mention these parallel holders. MagKeepers.com. The spring things just didn't make sense to my rookie brain. These looked cool and really hold things in place.

Bottom line...not a Kurt in fit or finish. Functionally, seems like a really nice, accurate vice and certainly an economical way to equip a new shop. Maybe less tears for a newbie when you accidentally end mill it. Recommended.

Is your business anything to do with your handle or is that one of your hobbies?