Thanks again, Titanium Knurler and gman10259- not that I didn't believe you, gman. Simple curiosity about how this worked.

I can't find a "max center height" for QCTPs, but assume there is no actual max- rather only what the operator is comfortable stacking up. LMS has some specs about min center height for AXA vs BXA:

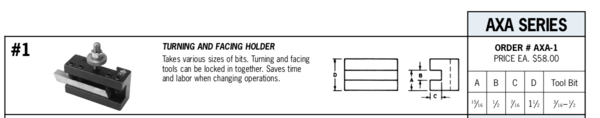

And Aloris has specs about tool holder size:

So I guess we can subtract the B dimension from the A dimension on the turning holder to get the height of the lower block. Then we can add in the 1/2" tool height to get the min height of the cutter relative to the bottom of the tool holder block bottom. For the AXA holder, that would be (.9375 - .5) + .5 = .9375 inches**. Taking this measurement and subtracting from the lathe's center height would indicate how low the tool would be from the center height at the lowest possible position on the tool post***. In this case, looks like the center height for the PM-1236-T is 1 7/32" or, 1.21875" so the tool on an AXA holder would fall (1.21875" - .9375") = .28125" below center height. Or in other words, using an AXA tool post would require raising the tool by .28125". My AccuSize tool holders seem to have at least .5" of adjustability and therefore indeed the AXA size should work just fine on this lathe (as we already knew from gman). That was interesting to investigate though. I wasn't sure how all this worked... Instead of specifying some reasonable guideline, Aloris simply states to email them and ask.

** I do realize that the A dimension would seem to imply the final height, however it should be noted that not all AXA tool holders have an exact 1/2" B dimension. In fact, my Accusize #250-001 holders seem to have closer to 9/16" capacity. Therefore it wouldn't always be true that the A dimension states the tool height relative to the bottom of the holder.

*** This also assumes that the bottom of the tool holder block could potentially rest on the compound at the lowest position of the adjustment screw. I'm not in front of my lathe at the moment, but I suspect that this might not be entirely true; there is probably a built in stop on the tool post disallowing the tool holder block from touching the compound. Therefore whatever this built in space is, it would be subtracted from the final calculation above.