- Joined

- Jun 12, 2014

- Messages

- 4,817

I was asked to to make two complete replacement controls systems for the PM-1440GT, both were designed to mount the VFD in the headstock cabinet in front of the bulkhead so everything is self contained within the cabinet. There are some differences in the circuit design depending on the VFD used, these days I prefer to do the build these systems for the Yaskawa GA500, as it seems to perform slightly better than the WJ200 in this particular lathe. Both systems are designed around use of the proximity stop system which uses a long range (3X) sensor allowing threading speeds of 600-700 RPM for a 10-12 pitch thread, the stopping repeatability is typically better than 0.001". It is most useful for threading, but also works well for blind boring and close in work near the chuck. There is 2-3 levels in stopping redundancy in the control system design, but nothing is 100% so proper awareness and safety needs to always be used.

Recent PM-1440GT control system install using the Yaskawa GA500 by Jake P.

www.hobby-machinist.com

www.hobby-machinist.com

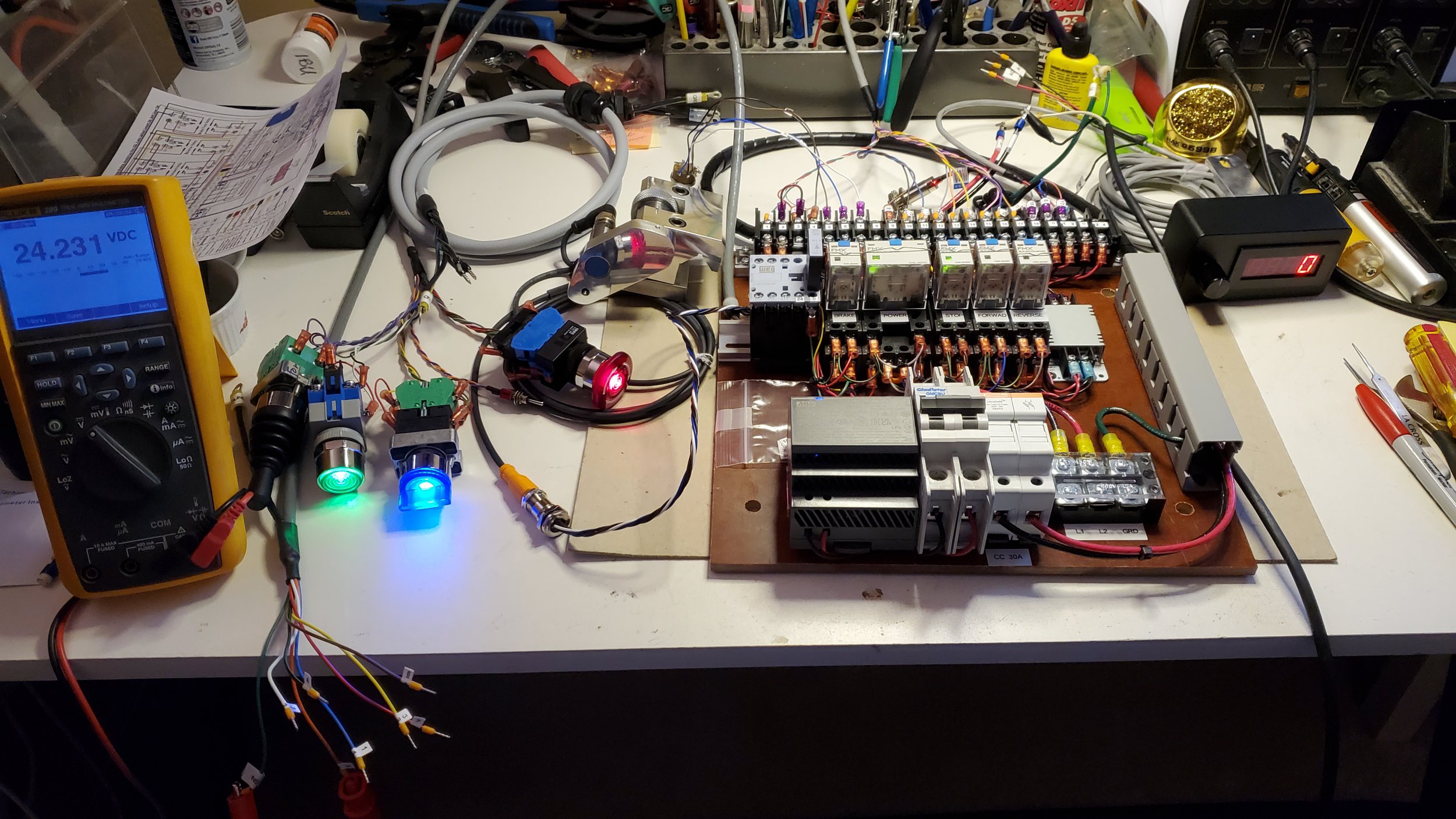

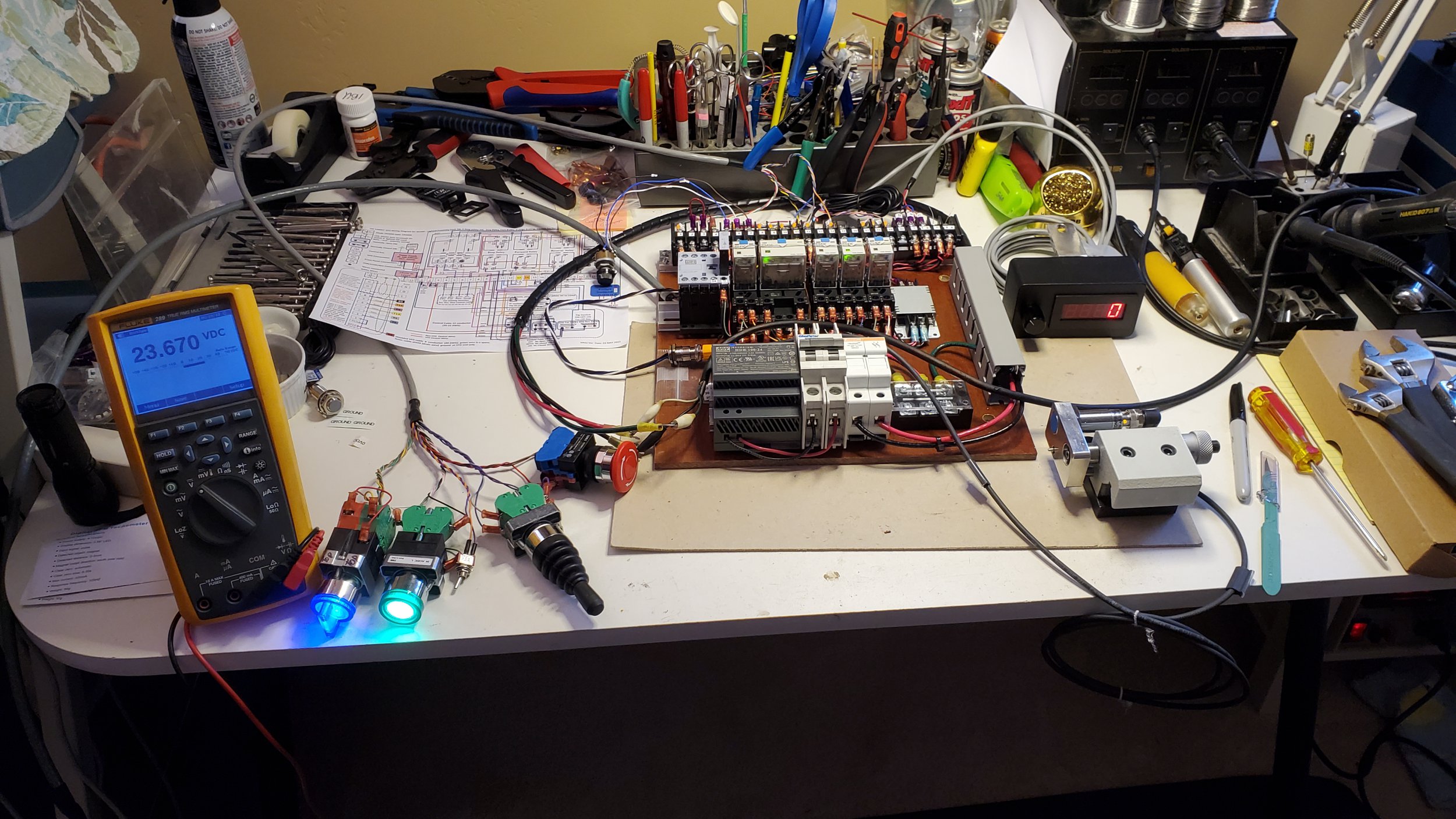

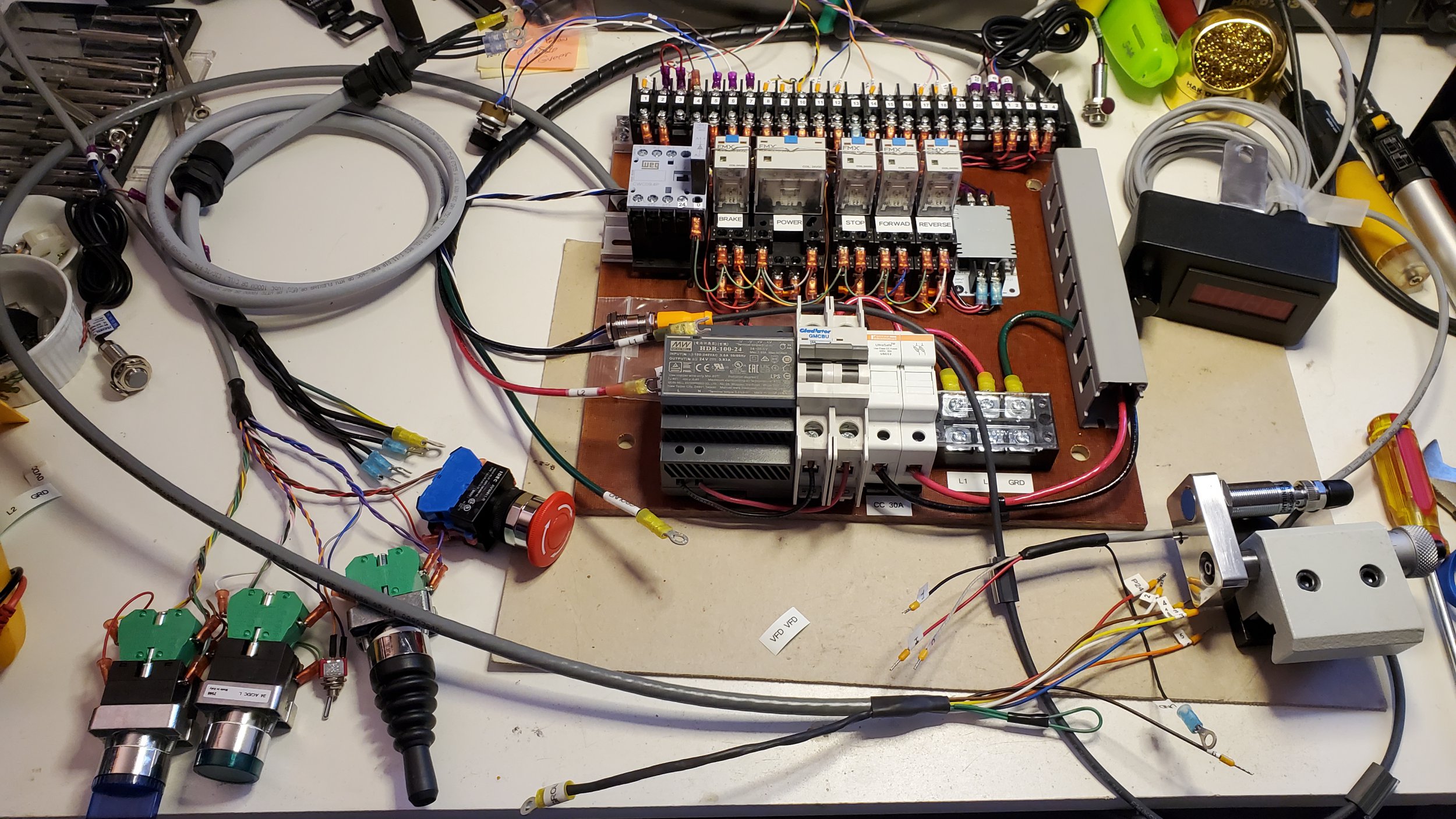

The design of the control systems includes low level 24VDC control wiring on the upper half of the board, and the high voltage (240VAC) is on the lower half, with HV cabling in chase on the right side. All the control cables and motor cable are shielded, they are grounded according to the application. All grounding terminates at the VFD. I still use relay designs, as they have proven to be very reliable and more cost effective then using a programmed controller. There is a coolant contactor which by default is wired for an a 24VDC air solenoid system, but also has the option of running the stock flood coolant or through the barrel coolant motor up to 1/2 Hp. There is a breaker that feeds the power supply, but also could be used for 120/240VAC sub systems, the VFD power is routed through 30A CC fuses. These systems include a tachometer and I mount the speed pot in the same enclosure, I like to use a mil-spec 3 turn pot. Sourcing parts has been a big problem for everyone, so for some parts I have gone to other suppliers and their costs have gone up significantly with increased shipping costs.

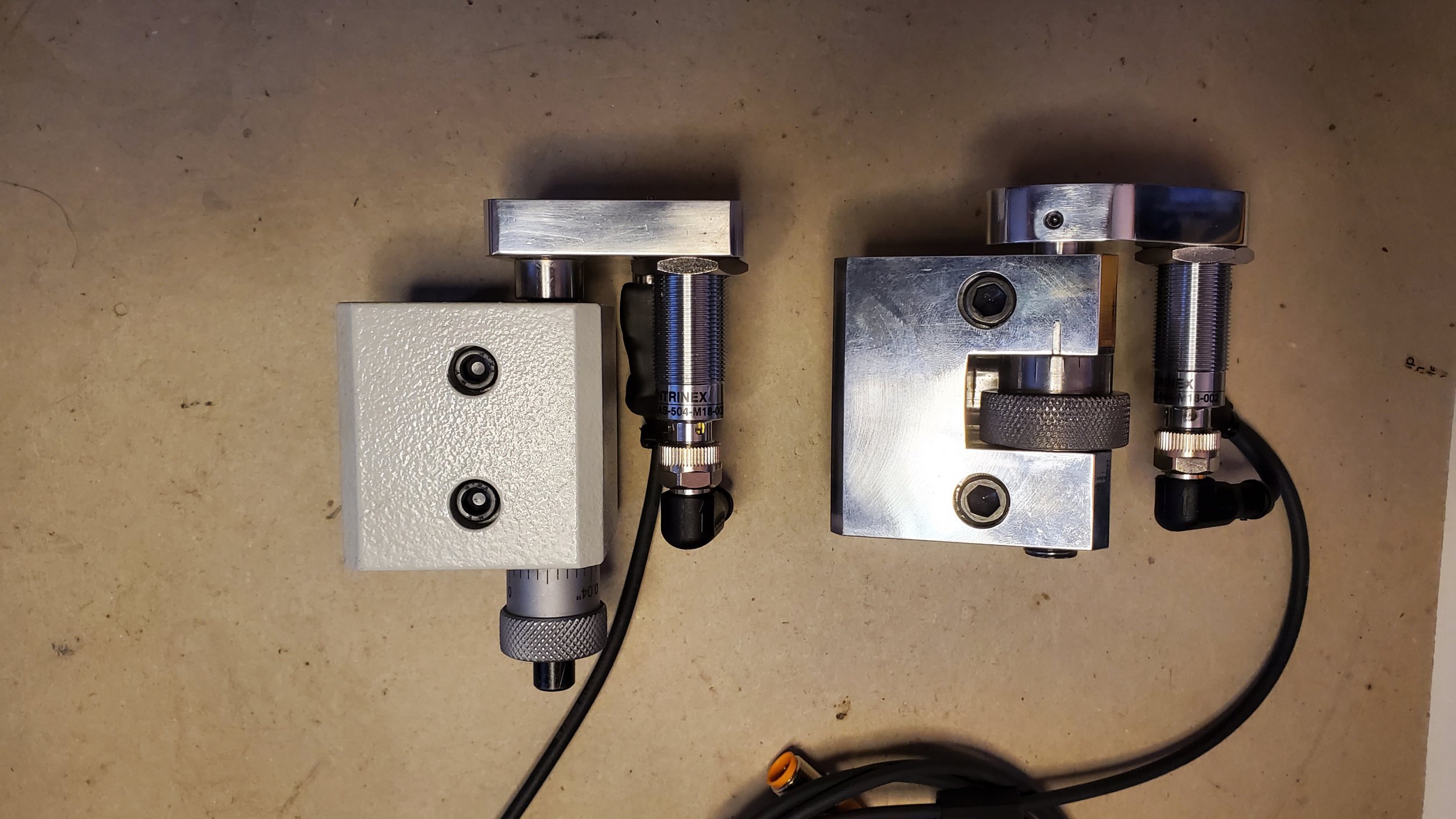

The Yaskawa GA500 PM-1440GT control system, I built the micrometer stop, as PM/QMT was out of stock. I have built both the stock design and a shorter body design which gives more travel and is a bit over 1 " shorter, so allows closer work near the headstock.

Always glad when these are done, shipped off an installed, usually takes me 2-3 weeks and many hours to source the parts to do these builds.

Mark

PM-1440GT Yasakawa GA500 VFD Control System

PM-1440GT Hitachi WJ200 VFD Control System

System with labels.

Stock Micrometer Stop vs. Custom with proximity sensor holder

Recent PM-1440GT control system install using the Yaskawa GA500 by Jake P.

1440GT Upgrades and Additions

Part One, VFD Conversion: As some of you may remember I had a 1340GT on order for many months and ended up finding a deal on a used 1440GT just before my 1340 was to be delivered. The thread with that story is here: https://www.hobby-machinist.com/threads/my-1340gt-story.95922/ Since...

www.hobby-machinist.com

www.hobby-machinist.com

The design of the control systems includes low level 24VDC control wiring on the upper half of the board, and the high voltage (240VAC) is on the lower half, with HV cabling in chase on the right side. All the control cables and motor cable are shielded, they are grounded according to the application. All grounding terminates at the VFD. I still use relay designs, as they have proven to be very reliable and more cost effective then using a programmed controller. There is a coolant contactor which by default is wired for an a 24VDC air solenoid system, but also has the option of running the stock flood coolant or through the barrel coolant motor up to 1/2 Hp. There is a breaker that feeds the power supply, but also could be used for 120/240VAC sub systems, the VFD power is routed through 30A CC fuses. These systems include a tachometer and I mount the speed pot in the same enclosure, I like to use a mil-spec 3 turn pot. Sourcing parts has been a big problem for everyone, so for some parts I have gone to other suppliers and their costs have gone up significantly with increased shipping costs.

The Yaskawa GA500 PM-1440GT control system, I built the micrometer stop, as PM/QMT was out of stock. I have built both the stock design and a shorter body design which gives more travel and is a bit over 1 " shorter, so allows closer work near the headstock.

Always glad when these are done, shipped off an installed, usually takes me 2-3 weeks and many hours to source the parts to do these builds.

Mark

PM-1440GT Yasakawa GA500 VFD Control System

PM-1440GT Hitachi WJ200 VFD Control System

System with labels.

Stock Micrometer Stop vs. Custom with proximity sensor holder