That would be the correct model for single phase input, 3Hp 3 phase output continuous torque/sensorless vector. Surprised about the comment on the WJ200 having mixed reviews, they are very durable, the programming can be a PTA but once running I have not heard of any issues.

The WJ200 needs two commands to JOG in a direction, the JOG just sets the frequency (6 Hz is the default), the second command needs to be a direction. This is usually accomplished with a one way diode between between the JOG terminal and the Forward or Reverse terminal. This is a common request I often get and currently I have been using a 2 way joystick to momentarily jog forward or reverse. A matter of preference.

The usual E-Stop in VFD systems would interrupt the VFD run inputs and implementing rapid braking. I see no reason to kill the system power, as this defeats the VFD safety features. Usual protocol is to have a main power disconnect switch, followed by a fuse or breaker, which then power the VFD. If there is that much current that you need to kill the power, then a breaker or fuse will trip long before you get to it. As mentioned, many machines use a momentary switch to activate a contactor to apply system power. most likely this is much easier then pulling power to the the front of the machine, and the contactor can be wired into other safety systems. I would just put a two pole switch on the machine and keep it simple.

Many of the parts I usually get from AutomationDirect, they have a wide selection and they have 2 day delivery, so most of the process is figuring out what you need. A few things like the brake resistor is from China, so those are worth ordering in advance as they can take 2-3 weeks to get here. I can provide a list of usual sources. As mentioned, you will need a 24VDC power supply 60-100W to run the relays, tach and possibly lights if you go that route. Also a step down converter for 12 VDC components like the tach and 12V lighting.

Last but not least, if you have a VFD with low voltage controls I do recommend using some form of electronic carriage stop that is fastened to your you micrometer stop. This can be something as simple as a plunger limit switch, or an electronic hall sensor. I have posted different designs, there is a number of ways to add this feature.

Probably best to send me a PM with your email, and I can work with you on your system. I am starting a new system build, and have to follow up on a few out in the field, so it may be 2-3 weeks until I can get the details to you.

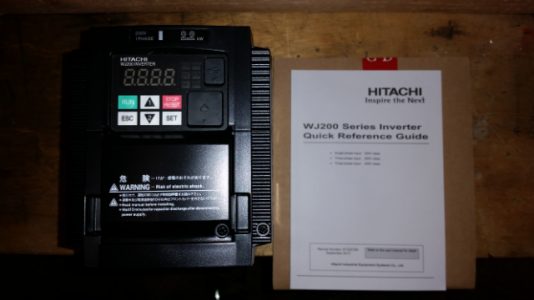

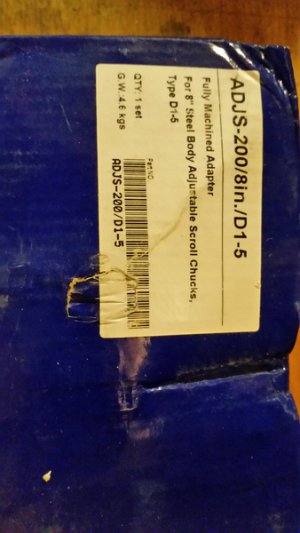

Please also consider where you are going to mount the VFD and the associated infrastructure, like breakers/fuse, disconnect switch, location of power supply, etc. There are a lot of pieces to the puzzle, depending on what you want to do. This shows some of the build components to consider:

http://www.hobby-machinist.com/thre...-did-you-do-in-your-shop-today.14637/page-327

Mark