- Joined

- May 13, 2019

- Messages

- 1,016

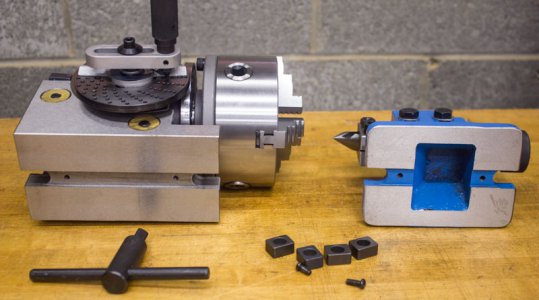

There seems to be a lot of interest here on the BS-0/1 dividing head on various sized milling machines. I bought the PM BS-0 dividing head recently and I thought I'd share some and ask some questions as well.

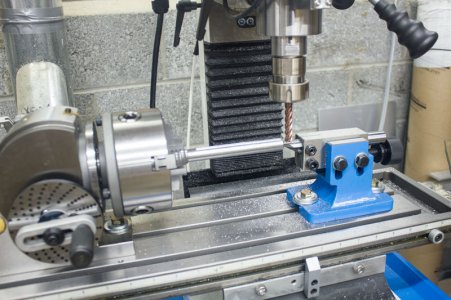

To me, I think the BS-0 dividing head is the right size for my PM-25 mill. I don't think I'd want to go any bigger. As it is, when I put the chuck vertical, there isn't lot of clearance left. Bigger might give no room for parts and cutters.

Be careful when using the tables in the manual that came with it. There are errors in there on settings for various divisions. I calculate everything manually and cross-check it with the manual.

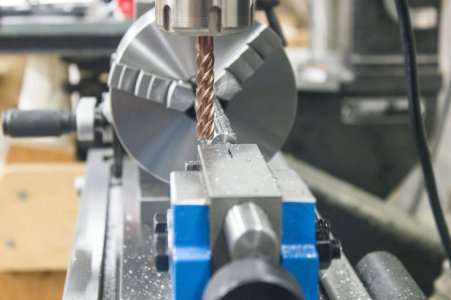

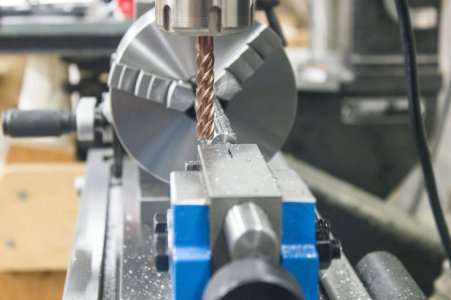

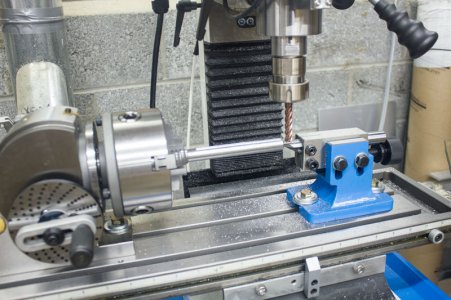

Here's some photos showing the size relative to the mill's table. I'm cutting some flutes on some 5/8" (~16 mm) stock here.

I needed to use an extra long cutter to clear the chuck jaws. Also, this is the first time I've used the tailstock. I'm assuming that the large SHCS on the bottom is to remove play in the center and the smaller screw on the top is to lock everything down? Is that correct? Getting everything aligned is a little time consuming since the screw pushes the center backwards (along Y axis). Plus getting the height right is a little tough as well using the two large hex head bolts. But, I was able to get it within 1 or so thou over the entire 4-1/2" length of cut. Overall, I'm very pleased with this dividing head.

I created a spreadsheet to calculate the Y and Z position of the end mill based on stock diameter, end mill diameter, and depth of cut. I cut at the 45 degree position.

To me, I think the BS-0 dividing head is the right size for my PM-25 mill. I don't think I'd want to go any bigger. As it is, when I put the chuck vertical, there isn't lot of clearance left. Bigger might give no room for parts and cutters.

Be careful when using the tables in the manual that came with it. There are errors in there on settings for various divisions. I calculate everything manually and cross-check it with the manual.

Here's some photos showing the size relative to the mill's table. I'm cutting some flutes on some 5/8" (~16 mm) stock here.

I needed to use an extra long cutter to clear the chuck jaws. Also, this is the first time I've used the tailstock. I'm assuming that the large SHCS on the bottom is to remove play in the center and the smaller screw on the top is to lock everything down? Is that correct? Getting everything aligned is a little time consuming since the screw pushes the center backwards (along Y axis). Plus getting the height right is a little tough as well using the two large hex head bolts. But, I was able to get it within 1 or so thou over the entire 4-1/2" length of cut. Overall, I'm very pleased with this dividing head.

I created a spreadsheet to calculate the Y and Z position of the end mill based on stock diameter, end mill diameter, and depth of cut. I cut at the 45 degree position.