- Joined

- Dec 29, 2013

- Messages

- 284

So I have had my 1340GT for about 3 years now and have always had plans to make a solid tool post riser and just never got around to it. Well, with my recent acquisition of a Fadal VMC, I figured it was a perfect project to learn a little bit. I have never seen in person, been around or operated a CNC machine until about 3 months ago, so go easy on me if things aren’t right somewhere. I’m still learning.

Anyways, on to it. The main 2 reasons for wanting a solid tool post riser is for the added rigidity I see other claiming and because I run several of my tools upside down, I needed the riser to be about ¼” higher than the compound currently is. I’ve been spacing my tool holders up with a piece of HSS for years and it is annoying.

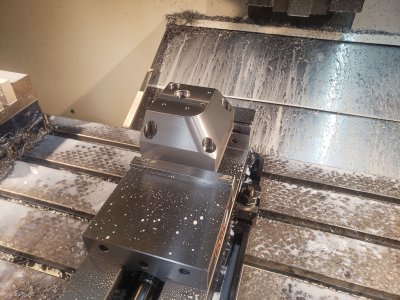

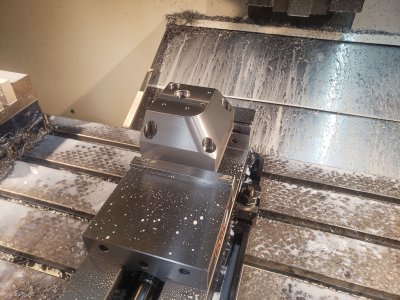

Started with a chunk of mild steel from eBay. This part was 2 setups, top side, flip and bottom side. Top side included contouring, 3d contouring for the slant sides, drilling, boring, rigid tapping and chamfering.

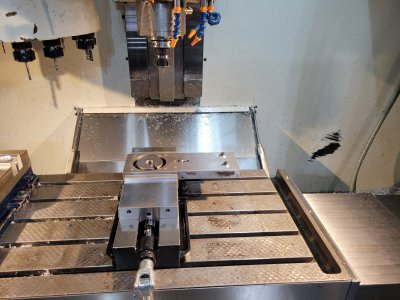

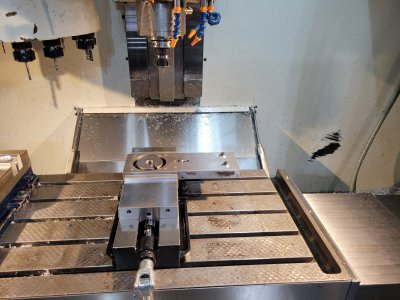

Next, flip the part. I wanted to have the boss in the middle that will locate in the hold of the carriage for added rigidity. I wanted it to be a close fit and that is what I got. Loving this machine.

Next was the “no turning back” point. Put the carriage in the vise and run the program. Fingers crossed. Simple drill, bore and then threadmill the threads because I did not have a bottom tap that would get the most threads from the hole depth. I could not go very deep without drilling into other features of the carriage underside. Also, I needed to locate on the center hole of the carriage as accurate as I could so everything would line up correctly. I left zero clearance for misalignment and figured I could come back and enlarge holes, etc. if I needed to. I didn’t need to tho, came out great.

I didn’t get any pictures making the tool post stud, but here it is. Threaded ¾-16 in the riser with a larger boss to locate/square up the post to the riser. The post is about .070 larger than the factory one, it has a nice slip fit through the tool post. It is also 1045 steel which combined with the larger diameter and method of attachment to the riser, should flex significantly less than the factory one. Top thread is 24 tpi which I figured would give me higher clamping force on the tool post. The nut is 12L14 which I have found to feel much nicer than regular steel, probably just in my head tho…

Let me know what you think...

Anyways, on to it. The main 2 reasons for wanting a solid tool post riser is for the added rigidity I see other claiming and because I run several of my tools upside down, I needed the riser to be about ¼” higher than the compound currently is. I’ve been spacing my tool holders up with a piece of HSS for years and it is annoying.

Started with a chunk of mild steel from eBay. This part was 2 setups, top side, flip and bottom side. Top side included contouring, 3d contouring for the slant sides, drilling, boring, rigid tapping and chamfering.

Next, flip the part. I wanted to have the boss in the middle that will locate in the hold of the carriage for added rigidity. I wanted it to be a close fit and that is what I got. Loving this machine.

Next was the “no turning back” point. Put the carriage in the vise and run the program. Fingers crossed. Simple drill, bore and then threadmill the threads because I did not have a bottom tap that would get the most threads from the hole depth. I could not go very deep without drilling into other features of the carriage underside. Also, I needed to locate on the center hole of the carriage as accurate as I could so everything would line up correctly. I left zero clearance for misalignment and figured I could come back and enlarge holes, etc. if I needed to. I didn’t need to tho, came out great.

I didn’t get any pictures making the tool post stud, but here it is. Threaded ¾-16 in the riser with a larger boss to locate/square up the post to the riser. The post is about .070 larger than the factory one, it has a nice slip fit through the tool post. It is also 1045 steel which combined with the larger diameter and method of attachment to the riser, should flex significantly less than the factory one. Top thread is 24 tpi which I figured would give me higher clamping force on the tool post. The nut is 12L14 which I have found to feel much nicer than regular steel, probably just in my head tho…

Let me know what you think...

you want to be a hobby machinist, and you need a part for your manual lathe, Then you bust out your CNC Mill, and make a b*t*hn' riser block, yeah, OK

you want to be a hobby machinist, and you need a part for your manual lathe, Then you bust out your CNC Mill, and make a b*t*hn' riser block, yeah, OK