Hi Mike,

I think you need to take another look at the software and settings. I cannot recall, but there may have been a check box (or similar enabling action) that allows you to make changes to some of the settings. I could be wrong, but I kind of recall that you have to enable the e-brake usage before you can change the value. (Search "Dynamic braking usage ratio" ? "b090" ? )

You will want to run the auto tune program when you hook up your motor, but I don't think this does anything for your e-brake resistor value setting. (see below)

When I looked back at my write up I see that the default program value is 35 Ohm, but changed the setting to 50 Ohms as I built a 50 Ohm resistor e-brake resistor bank. I provide all of the VFD programmed settings at the end of the Part 2 of my report. Note that there are columns showing the values. The first column is the code VFD data ID and this is b097. The second column is the description, the third column is the programmed value, the 4 column is the default values, and the last column are the possible choices you can make. You will find the build instructions at page 12, as well as my description of how to build a 37.5 Ohm resistor value. I used individual 25 Ohm 50 watt resistors wired in series and in parallel to build this as the final assembly was considerably smaller than the commercially available "Sea Slug" braking resistor. I used the 25 Ohm 50 watt individual resistors because they were inexpensive and easy to get. The drawing of the resistor bank is shown in Figure 6, and is shown in a couple of the photos. i.e.

https://www.hobby-machinist.com/attachments/09a-mag2616-braking-resistor-imag2616-jpg.378089/

The programing list, at the end of my Part 2 report, pdf page 45+, shows in "yellow high lite" the lines that I changed from the default values so it is pretty easy to spot them. Unimportant are the "trip event records", "d083", at the end of these pages. They represent some of the testing I was doing and I should have deleted them.

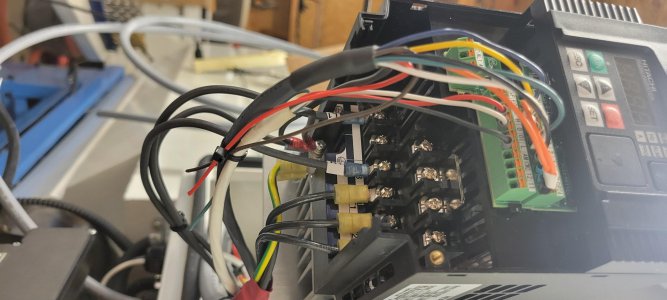

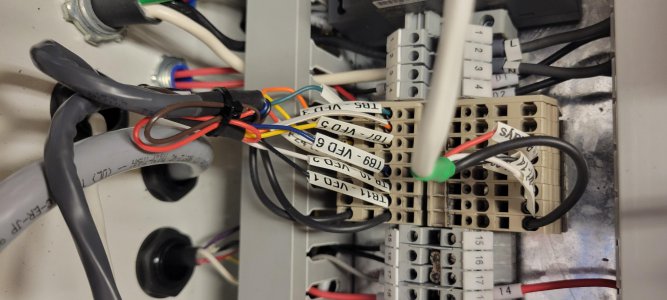

Also the values of the intelligent inputs are assigned there, but you may also see the values in the image I posted earlier of my VFD input labels. I think they were #7 for the Reset, #4 for USP, #6 for Reset, #5 for EXT, as well as the standard #s 1, 2, 3 for forward, reverse, jog.

The pdf Part 2 file that I uploaded should be searchable. Just search for "BRD" or "b097" and you should see the e-brake value listed as 50 Ohms rather than 35 Ohms. In the software you will want to search for "C001" to "C007" to change the intelligent input functions. The active states are changed at "C011" to "C017".

PS. I initially found the VFD programing software to be a little obtuse, but once I got the hang of it it was easy and reliable. I reprogrammed the VFD multiple times. I just used my day to day laptop which was running Win7. (It still is, as I have other, very expensive, software that will not run on Win10 or 11! I also have laptops running Win10 as there is newer software that will not run on Win7.)

In the end, many of my VFD settings are not much different from what Mark had described. His pass postings about the VFD were helpful and reassuring. Figuring all of the VFD info out using the 600+ page manual was a bit tedious, but I think I read it all more than once!

Dave L.

PS. If you do not find the programing table at the end or my Part 2 document let me know and I will post it here or message me with your email address and I will sent it to you directly.

https://www.hobby-machinist.com/att...-vfddescript-links-dnl-l910_1440b-pdf.378083/