- Joined

- Jun 12, 2014

- Messages

- 4,811

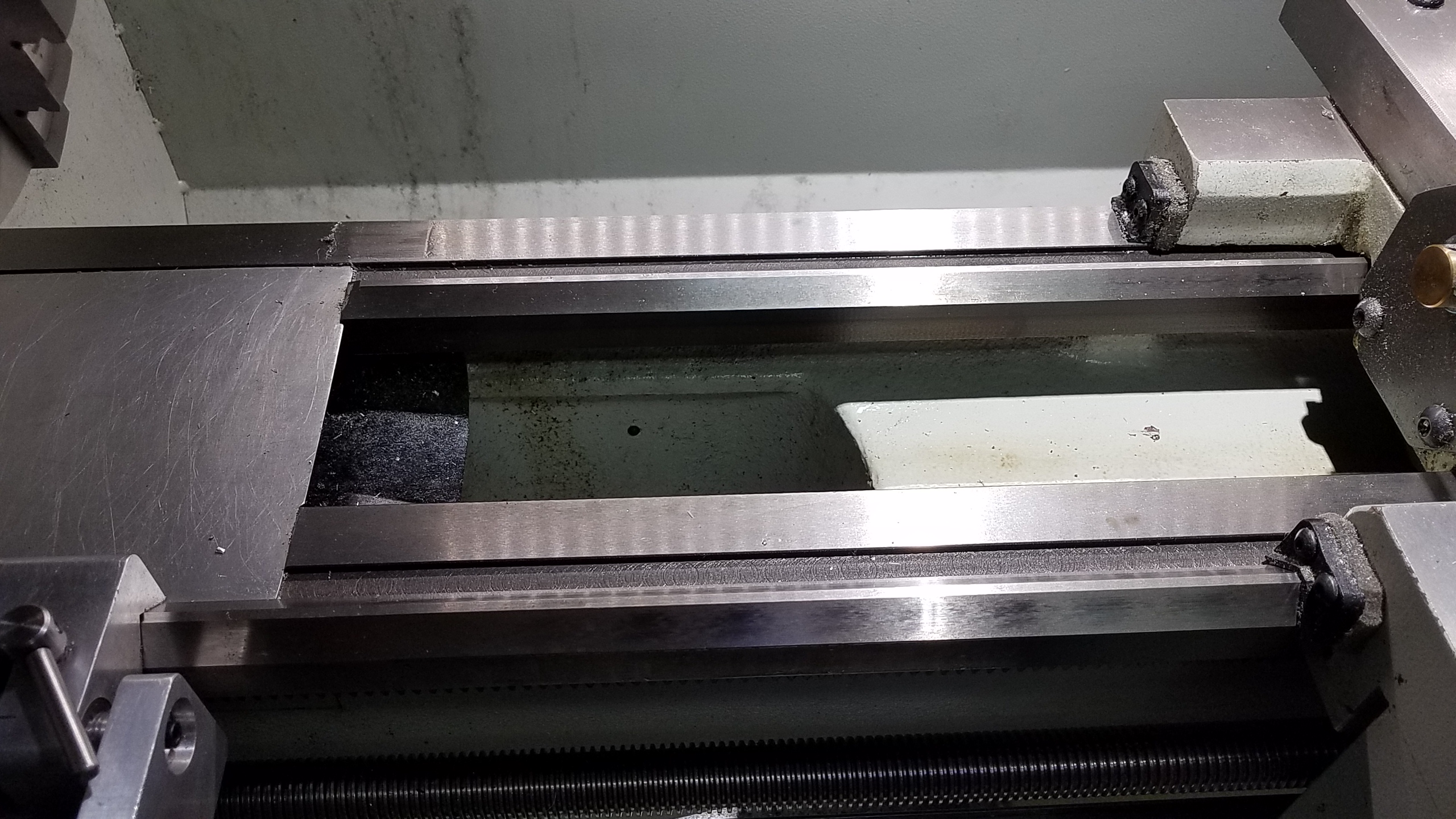

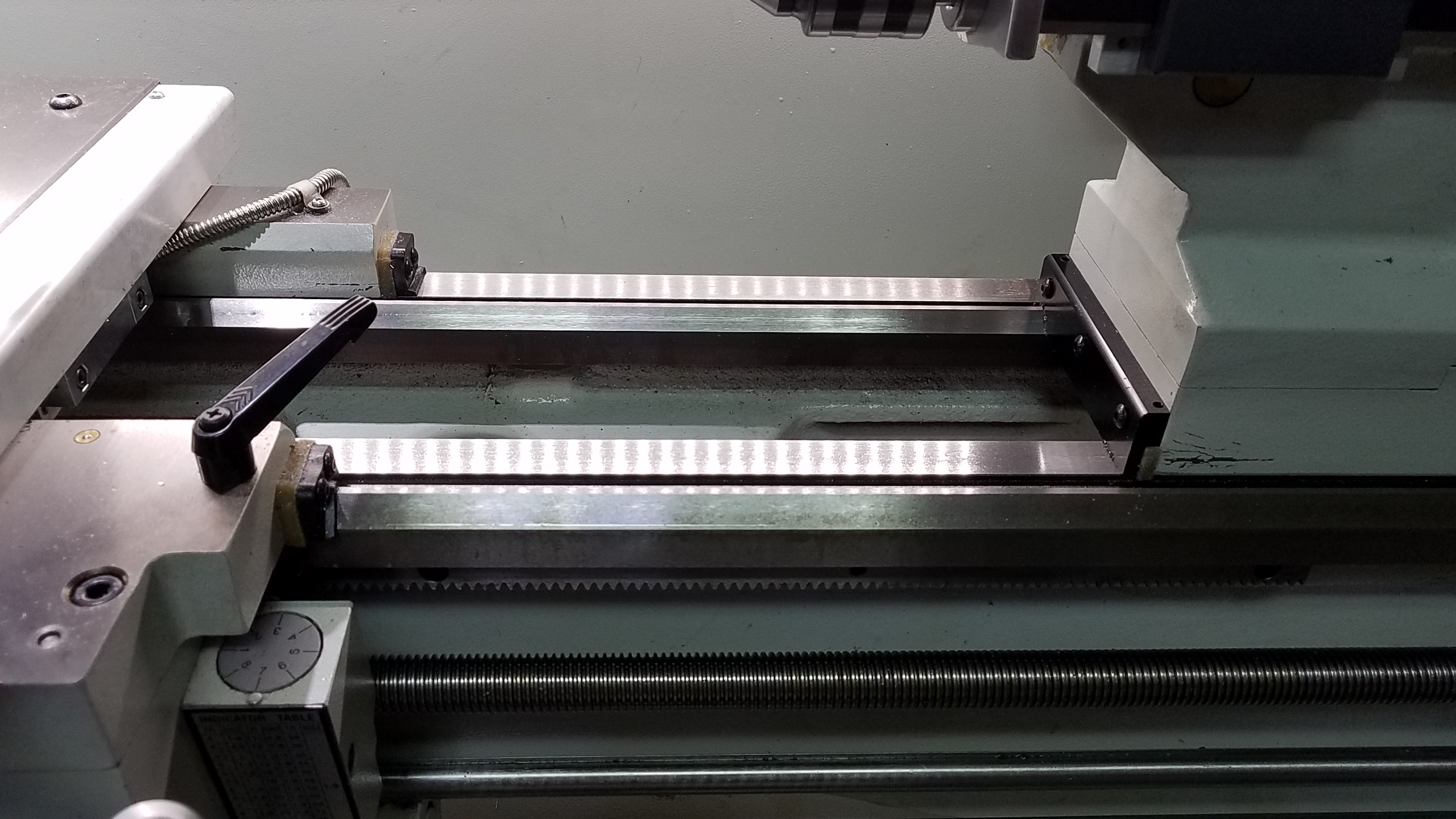

You can get some high spots that will get a bit polished, the bed is induction hardened, so I would expect the carriage to seat in from the scrapping. This is my 1340GT after several years, you can see some spots where the bed was a bit more polished. I have been using Vaculoine 1409 and added felt wipers behind the rubber that I also would apply oil to. Your jet ways looks likethey have been worn smooth, there is a small amount of the original grinding marks at the edges of the way.