-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM935 Hitachi WJ200 setup

- Thread starter kb58

- Start date

I found today the it it parameter B037. You need to change it to 0 and all the parameters will show. I would think that the manual being so in depth would state that as the first thing to change when you do the power up. I found this out today by doing an internet search for Wj200 drive does not show all parameters.

The mill is up and running making chips. I just need to get the pot so that I can change the drive hertz on the fly.

Roger L

The mill is up and running making chips. I just need to get the pot so that I can change the drive hertz on the fly.

Roger L

- Joined

- Apr 17, 2015

- Messages

- 323

Looks like we have different motors. My PM935 has a 4-pole only motor.

I have the same model motor on mine as you do. Its older (2015) and has fractionally different amp rating but a 4 pole 1720 RPM motor. Are you able to run more than 60Hz? If so what did you change to make that possible. I'd like a bit more range and RPM if I could get it.

- Joined

- Jan 10, 2019

- Messages

- 1,042

Not as of yet (full time job and all) but nothing's stopping me. There's a parameter for setting max Hz, which I've left along for now. In another thread I brought this up, how the motor itself is rated at 1720 RPM, yet PM states that with a VFD, this mill can go to 5000 rpm. Thing is, I remember PM telling me that since the motor is rated for 60 Hz, going any higher is on us. I agree with this, yet because they say that, I feel that it's a little misleading to state as fact in the specs that it can be run to nearly 120 Hz - or whatever (5000 / 1720) * 60 is.I have the same model motor on mine as you do. Its older (2015) and has fractionally different amp rating but a 4 pole 1720 RPM motor. Are you able to run more than 60Hz? If so what did you change to make that possible. I'd like a bit more range and RPM if I could get it.

- Joined

- Jun 12, 2014

- Messages

- 4,817

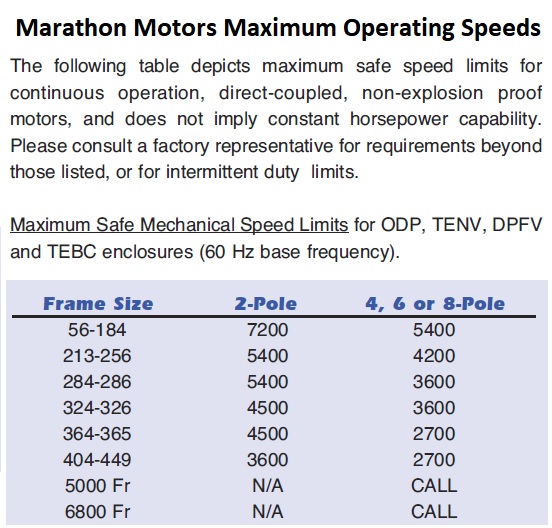

According to their site information the rating is for the spindle speed not the motor speed. Based on the TS speed range this equates to a motor speed of around 110 Hz to achieve a 5000 RPM spindle speed. Typically you see 4200-4500 RPM as the top end spindle speed for these type of mills which would work out to ~90-100 Hz range. I do not speak for QMT, but from what I have been informed by others and also the motor manufacturer specs is that 80-90 Hz is quite a conservative upper operating point for a newer 4P motor. It is what I specify for almost all my lathe and mill VFD builds with 2-3Hp 4P 3 phase motors. Beyond 90 Hz, I typically do not recommend it, and I often suggest that with belt drives that people change the belt drive ratio so the maximum spindle speed is not exceeded.The PM-935 TV version has a maximum spindle speed of 4200 RPM. My knee mill it is 4500 RPM.

Although 4P motors can often go to 2 X their base speed, their performance tends to drop off above 90-100 Hz vs. inverter/vector motors which can maintain full Hp up to their max speed (2-3X their base speed). The two speed constant Hp which comes on some PM mills is rated at 1720/3340 RPM so there is no issue with using the 4P winding and using a maximum speed of 3340 at 120Hz when using a VFD.

Nice install job on your 935.

Although 4P motors can often go to 2 X their base speed, their performance tends to drop off above 90-100 Hz vs. inverter/vector motors which can maintain full Hp up to their max speed (2-3X their base speed). The two speed constant Hp which comes on some PM mills is rated at 1720/3340 RPM so there is no issue with using the 4P winding and using a maximum speed of 3340 at 120Hz when using a VFD.

Nice install job on your 935.

Last edited:

- Joined

- Oct 27, 2016

- Messages

- 286

I have the stock motor and I've set mine to run from 30 to 90 hertz, nothing gets too hot at those settings and I've been running my mill for hours at a time.

I think that's what Mark Jacobs suggested when using the stock motor.

David.

I think that's what Mark Jacobs suggested when using the stock motor.

David.

- Joined

- Oct 14, 2014

- Messages

- 1,971

I have 4 pole spindle motors with VFD on three mills and two lathes...

I set them all to 4500 RPM max. and have not had trouble with years of operation.

My thinking was simple. 2 pole (3600) and four pole (1800) are made exactly the same inside. Then there surely is a large safety margin for centrifugal forces ripping the motor apart. Also 4500 on a decent bearing is no big deal.

I set them all to 4500 RPM max. and have not had trouble with years of operation.

My thinking was simple. 2 pole (3600) and four pole (1800) are made exactly the same inside. Then there surely is a large safety margin for centrifugal forces ripping the motor apart. Also 4500 on a decent bearing is no big deal.

- Joined

- Apr 17, 2015

- Messages

- 323

I found the command, A004 is the setting for max Hz. I see the 935TV model runs to 4200 RPM. It looks like they use the same head and spindle assembly on the 935, 949 and 1054 models and the parts list supports this. All of those machines have max RPM of 4200 in the variable speed model. Based on that I think its safe to increase the max Hz by 15% to 20% and see how the spindle bearing temp responds. From what I have read a 4 pole motor would not exceed its balance rating until 135 Hz. I would not come anywhere near that number to get where I would like the speed to be. Loss of torque is the trade off but since higher RPM would be used with small cutters the torque needs would be reduced.Not as of yet (full time job and all) but nothing's stopping me. There's a parameter for setting max Hz, which I've left along for now. In another thread I brought this up, how the motor itself is rated at 1720 RPM, yet PM states that with a VFD, this mill can go to 5000 rpm. Thing is, I remember PM telling me that since the motor is rated for 60 Hz, going any higher is on us. I agree with this, yet because they say that, I feel that it's a little misleading to state as fact in the specs that it can be run to nearly 120 Hz - or whatever (5000 / 1720) * 60 is.

- Joined

- Feb 6, 2013

- Messages

- 3

My PM-935TS just arrived a few days ago!

They didn't have a single phase 220 in stock so I got the 3 phase and the same Hitachi controller.

So far so good. Will earmark this thread for info on the remote control stuff.

Thank you so much for sharing. This is a huge help.

They didn't have a single phase 220 in stock so I got the 3 phase and the same Hitachi controller.

So far so good. Will earmark this thread for info on the remote control stuff.

Thank you so much for sharing. This is a huge help.

- Joined

- Dec 26, 2015

- Messages

- 2,079