- Joined

- Aug 7, 2020

- Messages

- 29

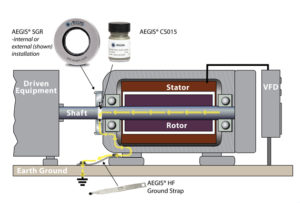

VFDs are scientifically proven to cause motor bearing damage over time. It's one of those things that is so negligible that it is nearly inconsequential I think. You can read more about it here:

est-aegis.info

est-aegis.info

How Do VFDs Cause Bearing Damage? | The AEGIS Blog

How variable frequency drives cause electrical bearing damage, explained as simply but accurately as possible.

est-aegis.info

est-aegis.info