- Joined

- Aug 7, 2020

- Messages

- 29

Today I got it cleaned up, powered up, and trammed in. I also cleaned up the massive 8" vise that came with it. My back is hating me for lifting that thing. Everything seems to work great except two small issues:

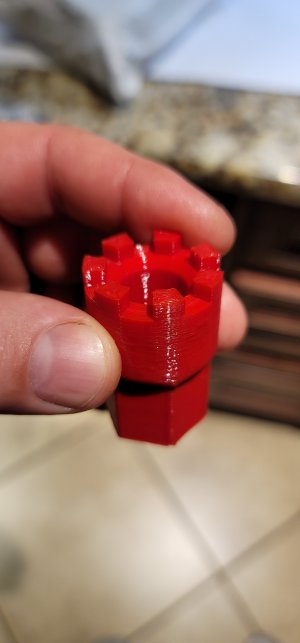

1. No elevation crank. It is a 30mm, 7-toothed crank and I can't seem to find any on eBay except for one that won't arrive from China until Oct. Maybe someone here has a lead on one? For now I'm going to try to 3d-print a Crank Yanker and if I can't eventually find something I guess I'll machine my own.

2. The quill auto-feed works if I hold the engagement handle in, but it does not stay in on it's own. My best guess is that there's a retaining ball / spring somewhere in there that is either worn or missing? Any ideas there? I'm looking in my manual but the resolution of those parts is so crappy it's hard to tell anything.

1. No elevation crank. It is a 30mm, 7-toothed crank and I can't seem to find any on eBay except for one that won't arrive from China until Oct. Maybe someone here has a lead on one? For now I'm going to try to 3d-print a Crank Yanker and if I can't eventually find something I guess I'll machine my own.

2. The quill auto-feed works if I hold the engagement handle in, but it does not stay in on it's own. My best guess is that there's a retaining ball / spring somewhere in there that is either worn or missing? Any ideas there? I'm looking in my manual but the resolution of those parts is so crappy it's hard to tell anything.