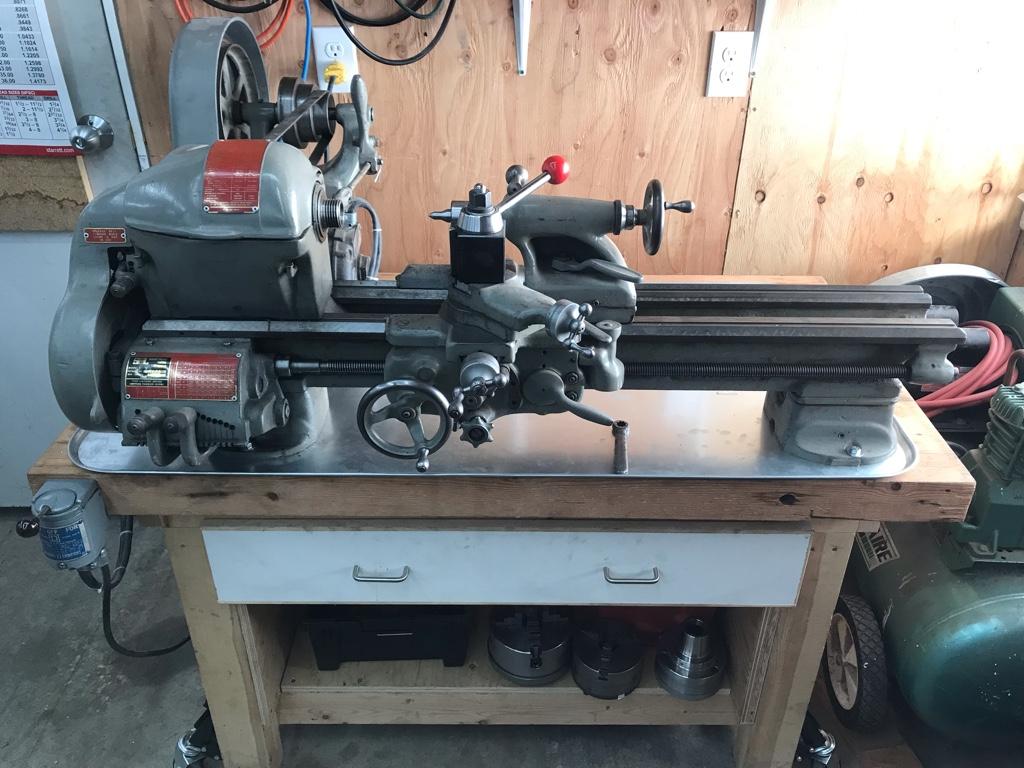

POTD was working on my 20-year old Delta miter saw. This particular model (36-255L) has line lasers on either side of the 12” blade to mark the cut. It works great, until it doesn’t. . . My wife went to cross cut a board; the saw worked, but the lasers didn’t.

Our Delta 12" miter saw with the handle off for "fixing"

View attachment 410548

Pulled the handle and put 3.7 V directly to the lasers and they fired up. Checked the output of the 110 V to 3V transformer and got nothing. Went on Amazon and got an 80 – 230 V to 3 – 20V LED driver for $7 delivered. Wired it in and fired up the saw; no lasers. Went back to the direct 3.7 V battery check and no lasers, what the heck?!? I checked the output of the LED driver at 50+ V DC; cooked the lasers. . . Stupid me, I should have checked the output voltage before firing up the saw. I’ll have to check on the difference (?) between an LED driver and a transformer. The LED driver label says it’s constant current, so voltage must be varied to maintain a constant Watt output? My electrical no-how pretty much stops at E=I*R and P=I*E.

3.7V battery fired up the lasers fine

View attachment 410549

50+ V from the new LED driver (ouch)! The lasers expect a max of ~5V.

View attachment 410550

Google’d replacement parts for the saw and found the laser modules for about $93 each (ouch). Pulled the lasers from their mounts and measured them at 10 mm diameter. Searched on Amazon for “Laser line LED” and found a ton for under $10. But the diameters were all 6, 9 or 12 mm. Ordered a couple of 9 mm ones. I didn’t show it, but ended up using a 110V to 5V USB plug-in transformer for the power source.

View attachment 410558

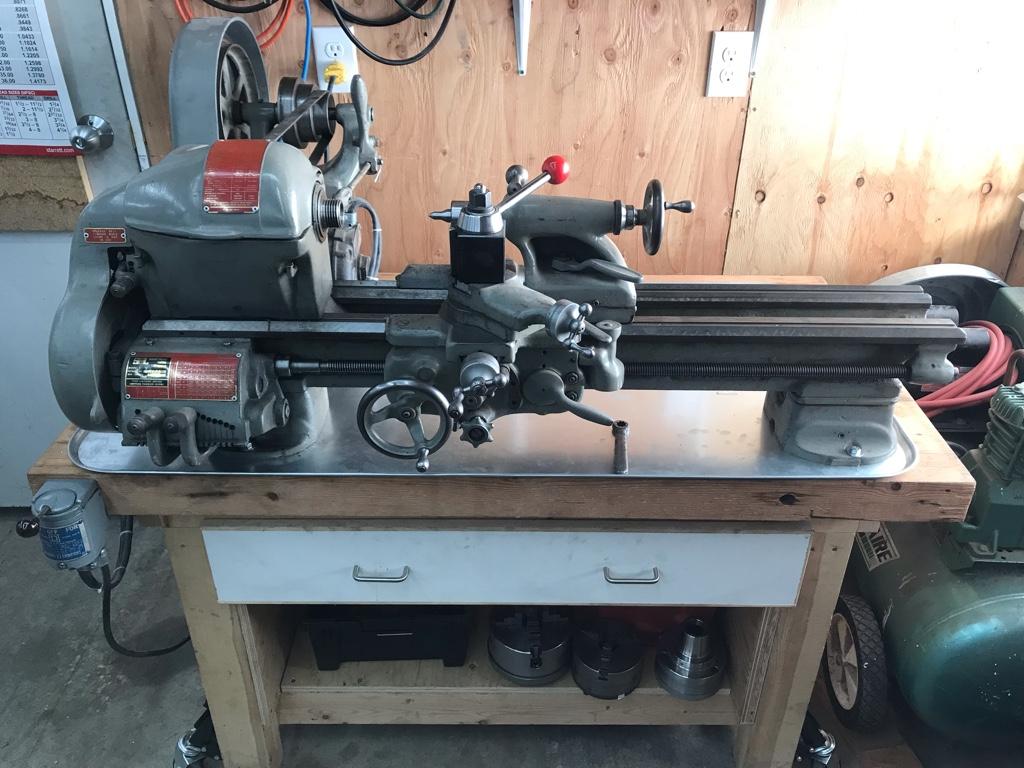

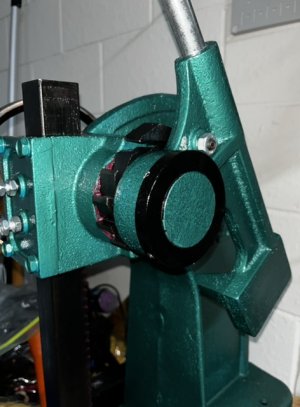

The original lasers have a hex on the end for adjusting the clocking of the laser line (clock the line parallel to the saw blade). This was added by drilling out a couple of ¼” nuts which were glued to the lasers with red Loctite. I went the quick route to build up the diameter from 9 mm to 10 mm by running some electrical tape around the lasers. Not my best fix, but I have a plan B. I found some 10 mm x 0.2 mm wall stock brass tubing on Amazon which will be here in a couple of days. The lasers press into a plastic detail, they are easy to pull. I'll Loctite a length of tubing in place for a more solid fix. The tape works fine, but I’m worried about plastic creep over time which could lead to misalignment.

1/4" - 20 nuts chucked up prior to drilling them out with a 9mm drill

View attachment 410551

Checking fit with a laser

View attachment 410552

Original lasers up top, taped up replacements below.

View attachment 410553

Mounting brackets for the lasers. The lasers press into a plastic detail. A screw on the side adjusts the position side to side. The hex nut on the back of the laser is used for clocking the laser line parallel to the blade. The headless set screw is used to flex the plastic mount side to side to adjust the laser so it's parallel to the plane of the saw blade.

View attachment 410554

All wired up and caulked (gasket goop) at the top. I didn't show it, but I misrouted the jumper harness from the saw handle to the lasers. The routing is important; the saw blade clipped both lines . . . I'm pretty good at soldering wires back together . . .

View attachment 410555

Back in business!

View attachment 410556

I adjusted the lasers by flushing a piece of white cardboard to the blade, then taped it in place. Then adjusted the clocking to be parallel with the blade/paper edge. Then adjusted the beam to be in the same plane as the blade with the headless set screw. Lastly, adjusted the side to side screw so the laser is scrubbing past the side of the blade to mark the kerf.

View attachment 410557

Thanks for looking, Bruce