-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Nov 25, 2015

- Messages

- 8,390

Until I make a power draw bar holder on rods and springs for my Clausing 8520, I made a hanger holder.

The clausing does not have a flat top to mount it on, so I will have to make a thicker top, and some jack screws for the front.

Anyway, I decided to do a quick mount for the butterfly impact.. Man this makes it so easy. wish I had done it long ago. The clausing is difficult to pop the mt2 taper sometimes. this makes it easy.

The hanger needs to offset away from the air connector, it uses two internal bosses in the casting.

Still have to drill a hole in the holder for the spring, and need to make some collars to lock things in from moving. and chamfer some edges. Those blocks were brazed on with alum brazing rod. I used a 2-56 just in case. The black marks are from my Kant Twist, they were glowing red, so the copper left a deposit.

The clausing does not have a flat top to mount it on, so I will have to make a thicker top, and some jack screws for the front.

Anyway, I decided to do a quick mount for the butterfly impact.. Man this makes it so easy. wish I had done it long ago. The clausing is difficult to pop the mt2 taper sometimes. this makes it easy.

The hanger needs to offset away from the air connector, it uses two internal bosses in the casting.

Still have to drill a hole in the holder for the spring, and need to make some collars to lock things in from moving. and chamfer some edges. Those blocks were brazed on with alum brazing rod. I used a 2-56 just in case. The black marks are from my Kant Twist, they were glowing red, so the copper left a deposit.

Last edited:

- Joined

- Nov 25, 2015

- Messages

- 8,390

- Joined

- Sep 8, 2019

- Messages

- 4,392

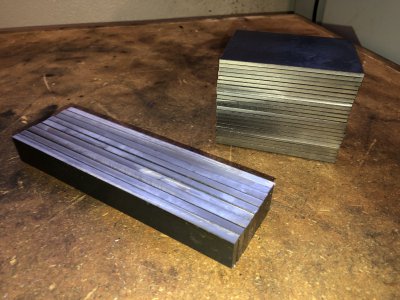

I need an R8 (and 3/4” shank!) collet rack (or tray), but I have zero money. I used some welding coupons & 1” bar (that I was going to use for backing straps for weld test plates) to make this *frame* for an aluminum R8 collet tray. I am saving up for three 12” X 12”, 1/4” aluminum plates.

I need to make 2 more of these. This one isn’t even done. I will need to trim the inside so that the sheet doesn’t interfere with the tool shanks.

The rack will be 3 stories high, & the posts will be fillet brazed 1-1/4”, .050” wall muffler tubing.

Yes, I ground my horrific 6010 welds, and I see that there is some underfill. It did turn out super flat, however!

Here are some of the single bevel (on 1/4”) & edge welds (two 1/8” sheets). These will go on the milling machine.

Next time I will knock off all the slag on the single bevel welds before I take the picture.

I need to make 2 more of these. This one isn’t even done. I will need to trim the inside so that the sheet doesn’t interfere with the tool shanks.

The rack will be 3 stories high, & the posts will be fillet brazed 1-1/4”, .050” wall muffler tubing.

Yes, I ground my horrific 6010 welds, and I see that there is some underfill. It did turn out super flat, however!

Here are some of the single bevel (on 1/4”) & edge welds (two 1/8” sheets). These will go on the milling machine.

Next time I will knock off all the slag on the single bevel welds before I take the picture.

Last edited:

No mine is different. I have a nut and then an acorn nut on top of the other. From what i gather you are suppose to use one nut to draw the collet up and the other is to tighten the drawbar. I end up having to give the acorn nut a good wack with my little 6/8 oz ballpeen and it pops downwell, I don't know if your 8530 has it, but mine has this cap. So the drawbar pushes up against it. But many times I have to hit my wrench over and over to get it to pop the collet. This just impacts it.

View attachment 413213

- Joined

- Sep 8, 2019

- Messages

- 4,392

- Joined

- Sep 8, 2019

- Messages

- 4,392

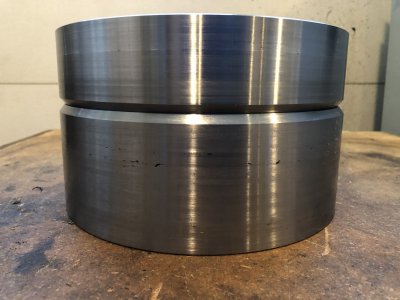

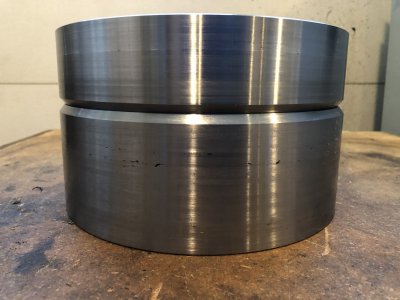

I finished these two recycled 8” Sch 40 pipe welding coupons. They have been used a lot, and their life is nearing an end. The wall thickness is down to .192”, so they are quickly becoming tube welding coupons.

I like making my own because I can eliminate pretty much all of the High/Low and get the landing just the thickness that I want.

I like making my own because I can eliminate pretty much all of the High/Low and get the landing just the thickness that I want.

- Joined

- Jul 14, 2017

- Messages

- 2,451

Today i spent some time cleaning the tire machine i recently bought. Started with taking off all the plastics, then i used a wire brush on a drill, fine sandpaper to clean off the rust from the sliding sufices. Then i decided to try out the machine, tested all the functions by their self they all work, it has couple of small air leaks but i put a tire on it and it takes and install it without any struggles. In Fact feels very strong, i'm very satisfied.

- Joined

- Sep 28, 2013

- Messages

- 4,319

Two projects. One, I finished up a collet rack for my ER 32 violets using a jalapeno chili popper rack. It was supposed to go on the wall, but after much work I realized that was a dumb idea as they kept falling out. So now it's in the tool box just under where I planned to put it on the wall

Just had to push the stuff already in it over to the left..

Also picked up another foster pup after Elektra got adopted last week, the sister of Bat Ears (Elektra). Hopefully we'll get her on her way to a new home soon

Just had to push the stuff already in it over to the left..

Also picked up another foster pup after Elektra got adopted last week, the sister of Bat Ears (Elektra). Hopefully we'll get her on her way to a new home soon