- Joined

- Nov 25, 2015

- Messages

- 8,399

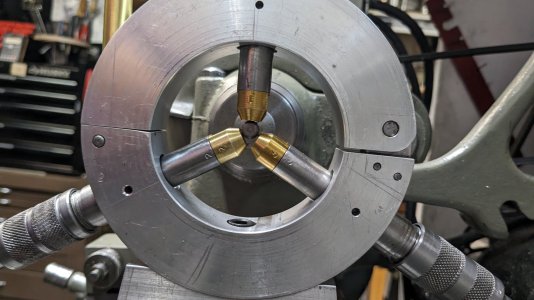

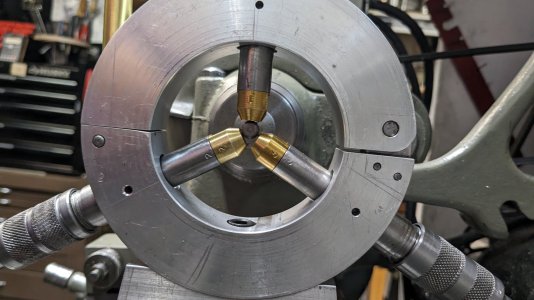

I made a mistake in my shop today. DAMN.

I made a rushed decision, not remembering why and what I decided to do on my steady rest. It cost me. I may have to remake the base.

Rather than use dowel pins and screws to secure the base like I decided, I wound up making a slot and matching mating surface to key the base in.

Then when I was done, I realized I just took my steady 1/16" out of center and lowered it. What lined up before, is now out .

Crap... need to make a new thicker piece out of steel for the base.

I made a rushed decision, not remembering why and what I decided to do on my steady rest. It cost me. I may have to remake the base.

Rather than use dowel pins and screws to secure the base like I decided, I wound up making a slot and matching mating surface to key the base in.

Then when I was done, I realized I just took my steady 1/16" out of center and lowered it. What lined up before, is now out .

Crap... need to make a new thicker piece out of steel for the base.