My first mill project.

View attachment 458620

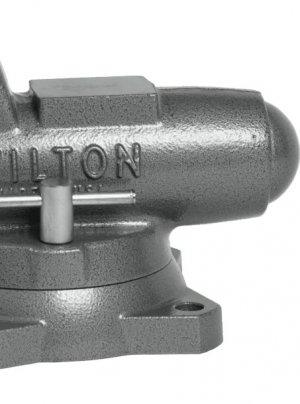

The Bridgeport I bought came with a 6" kurt vise but had no jaws. I just finished this set as my first project. I know the surface finish is less than desirable. I was experiment with speeds and feeds and getting to know the machine. I did all facing with a a 3/4 endmill. My final operation was the one laying flat and that came out buttery smooth other than the rough start. I think im definitely going to purchase a power feed after doing all of that by hand. The Vevor power feed seems to pretty good bang for your buck from the reviews ive seen.

View attachment 458621

Heres the other side where I was definitely going too fast. They are actually pretty smooth to the touch just not visually appealing. I also did some gib adjustments about halfway through the process. Had 2-3 thou play in the x axis.

These will do for now. I think a fly cutter is definitely on my short list. May be my next project.

...

The odor from these mats tho':

The odor from these mats tho':