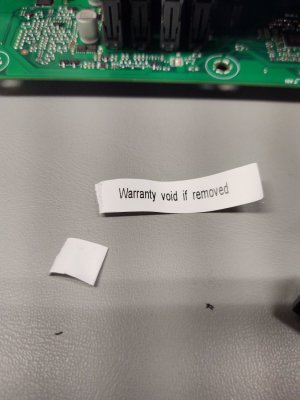

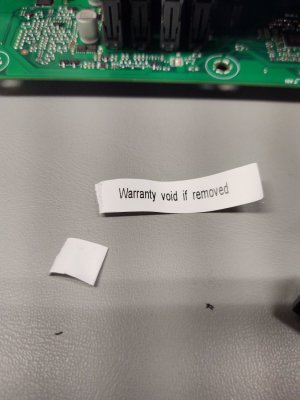

After yesterdays machining fiasco, I opted to do something different. First and foremost, I voided a warranty!

This is hobby machinist fare, I promise! It's for the new CAD machine here in the shop.

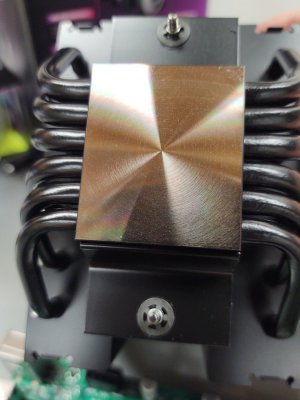

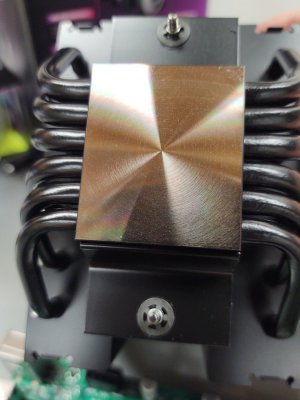

Attached a CPU to a main board with one of these aluminum retention brackets, rather than the stock intel spring loaded job. I really wasn't happy with the amount of force the spring puts on the board. It actually bends the carrier behind the CPU and some claim that they actually bend the CPU. This is bad for cooling, because the CPU doesn't mate well with the cooler.

Anyway, this bracket is very nicely machined and anodized. As is the bottom of the CPU cooler. This is supposed to be a monster air cooler, and it really appears to be well built. Perhaps I should lap the mating surface???

Overall, it went together well. This is the fourth one of this exact system (except the CPU cooler) I'm building this week. The others were at work. . One more next week next week at home for someone else.

It turns out pretty clean, all things considered. I did drop in a Nvidia T1000 4Gb Video card.

All good, Except for the stupid CPU cooler comes with unicorn-puking-rainbow fans!

Ahhhhh! MY EYES, I CAN'T SEE!

Those are going to get replaced with a better, blacker, non-flashing, non-epilepsy causing, higher CFM fan ASAP!

But until then, it'll run some ram tests.