- Joined

- Nov 3, 2023

- Messages

- 37

Something on the small side...

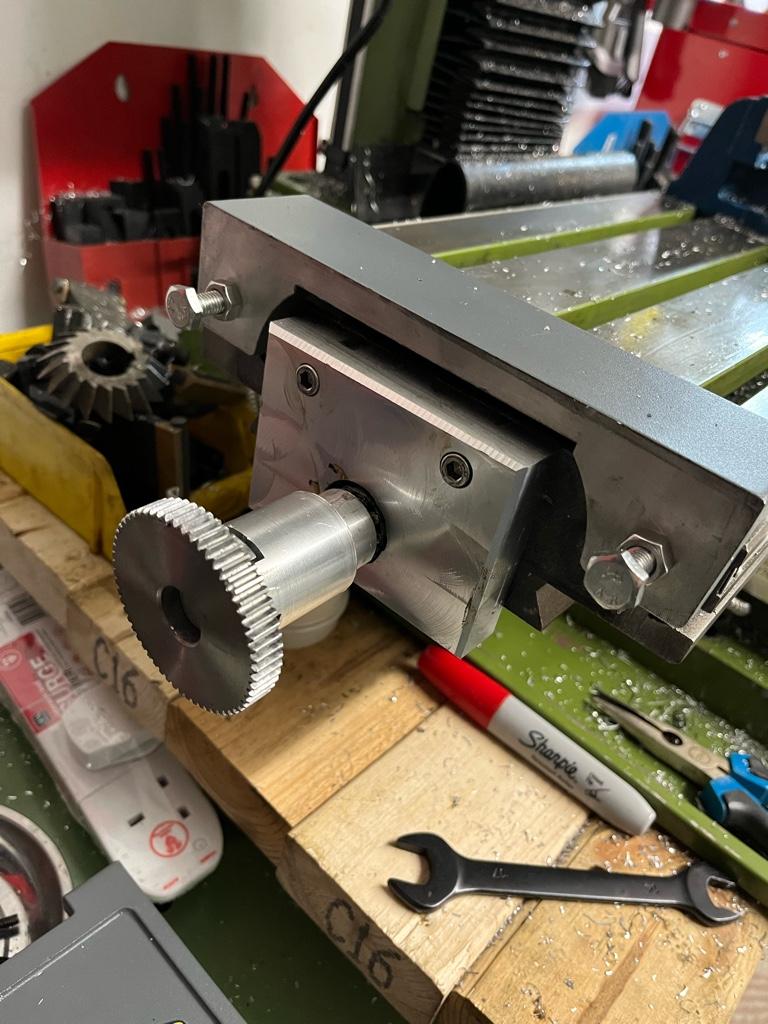

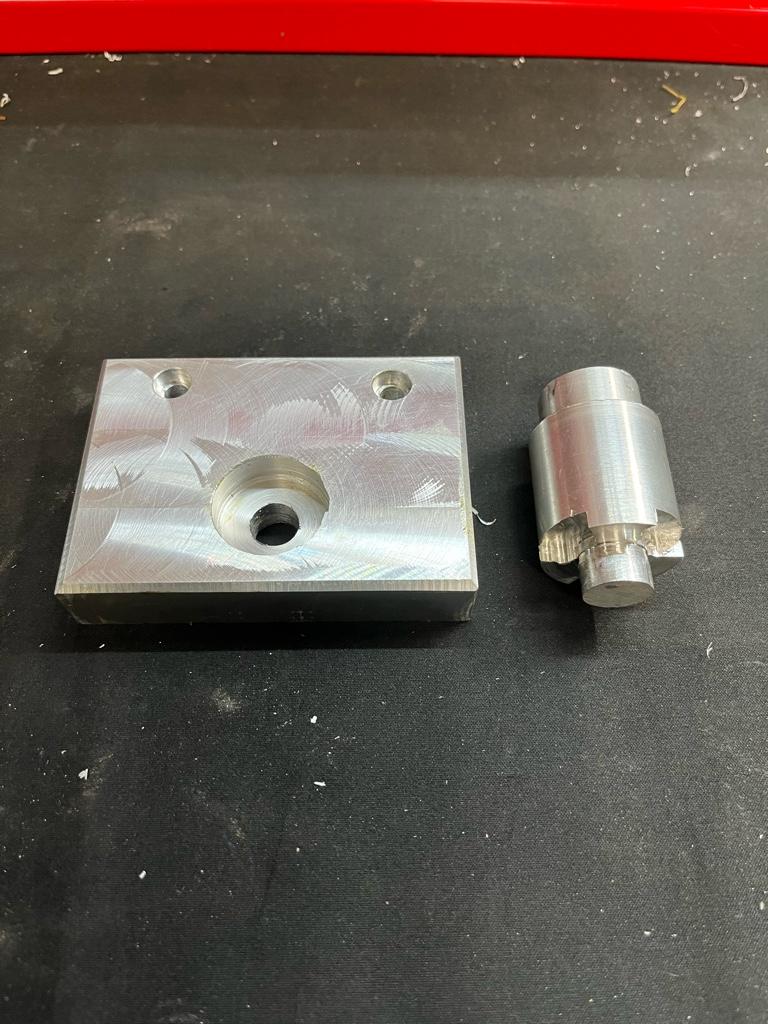

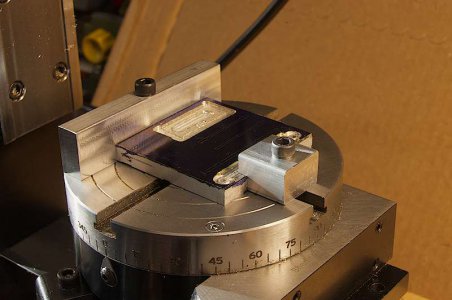

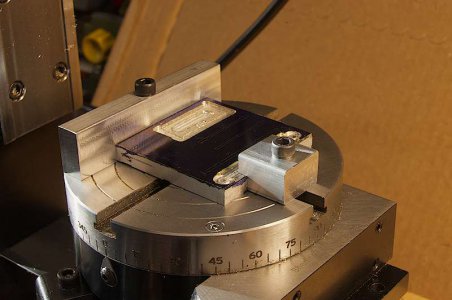

Learning this stuff as I go, first project is cutting teeny valve gear parts for my HO scale locomotive from 0.02" brass sheet. The siderods have crankpin bearings that make nice radii along the rod, so I'm working with the rotary table. Did some experimentation with various workholding, came up with this:

The workpiece is a 2x2" sandwich of 1/4" aluminum and the 0.02" brass glued together. I need to be able to slide the work up and down the X axis to center each crankpin for cutting the radii, so I made a self-squaring fence (has a small key cut in the bottom to fit the t-slot) and a clamp cut specifically to fit the sandwich. Not shown are the 0-80 screws I install in each of the drilled crankpin bearing holes to further stabilize the part as I cut it from the sheet. Haven't actually cut anything with the setup yet, but I have high hopes...

Learning this stuff as I go, first project is cutting teeny valve gear parts for my HO scale locomotive from 0.02" brass sheet. The siderods have crankpin bearings that make nice radii along the rod, so I'm working with the rotary table. Did some experimentation with various workholding, came up with this:

The workpiece is a 2x2" sandwich of 1/4" aluminum and the 0.02" brass glued together. I need to be able to slide the work up and down the X axis to center each crankpin for cutting the radii, so I made a self-squaring fence (has a small key cut in the bottom to fit the t-slot) and a clamp cut specifically to fit the sandwich. Not shown are the 0-80 screws I install in each of the drilled crankpin bearing holes to further stabilize the part as I cut it from the sheet. Haven't actually cut anything with the setup yet, but I have high hopes...