I was thinking a SB9 pully set would work, but right now I just want to get her going , and will move to that down the road. But thanks for confirming that this is the right idea. I am wondering if a Logan set might be a better/cheaper fit, so will have to look into that at some point also, but no rush, as I found a 4L step pully that would match what was on it when found, which will get me going on it.

But, here is where we are:

Getting the table tops, yes plural, poly coated. I am using two pieces of butcher block, as I couldn't find a single piece big enough at a price I was willing to pay that would work. Seriously, I am not going to pay as much for that as I paid for the mill! But I bolstered the two pieces on top of 2x4" and 2x8"s to strengthen and give me additional height. The base is from a Delta table saw/jointer combo I picked up for $20 at a garage sale, strong and good looking with storage underneath. That is where my Grandfathers Kennedy sits now.

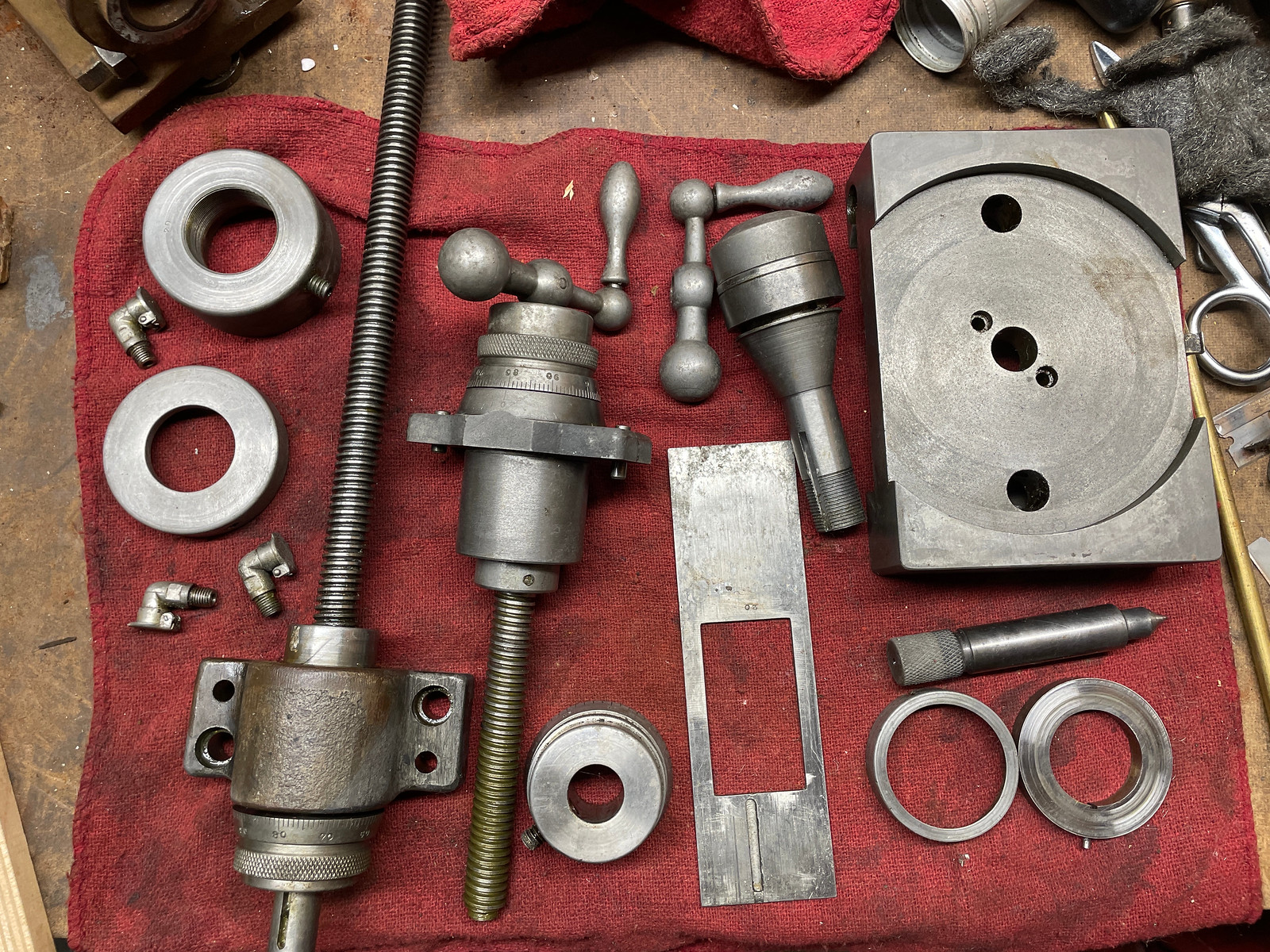

A bunch of stuff has arrived to finish this project off, but, as with every McMaster Carr order I place, I find three things that I need to order the next day. In this case, T nuts and longer mounting screws than my local Ace has. Right now I have place holder screws in to help locate the machine, but I need to upgrade those.

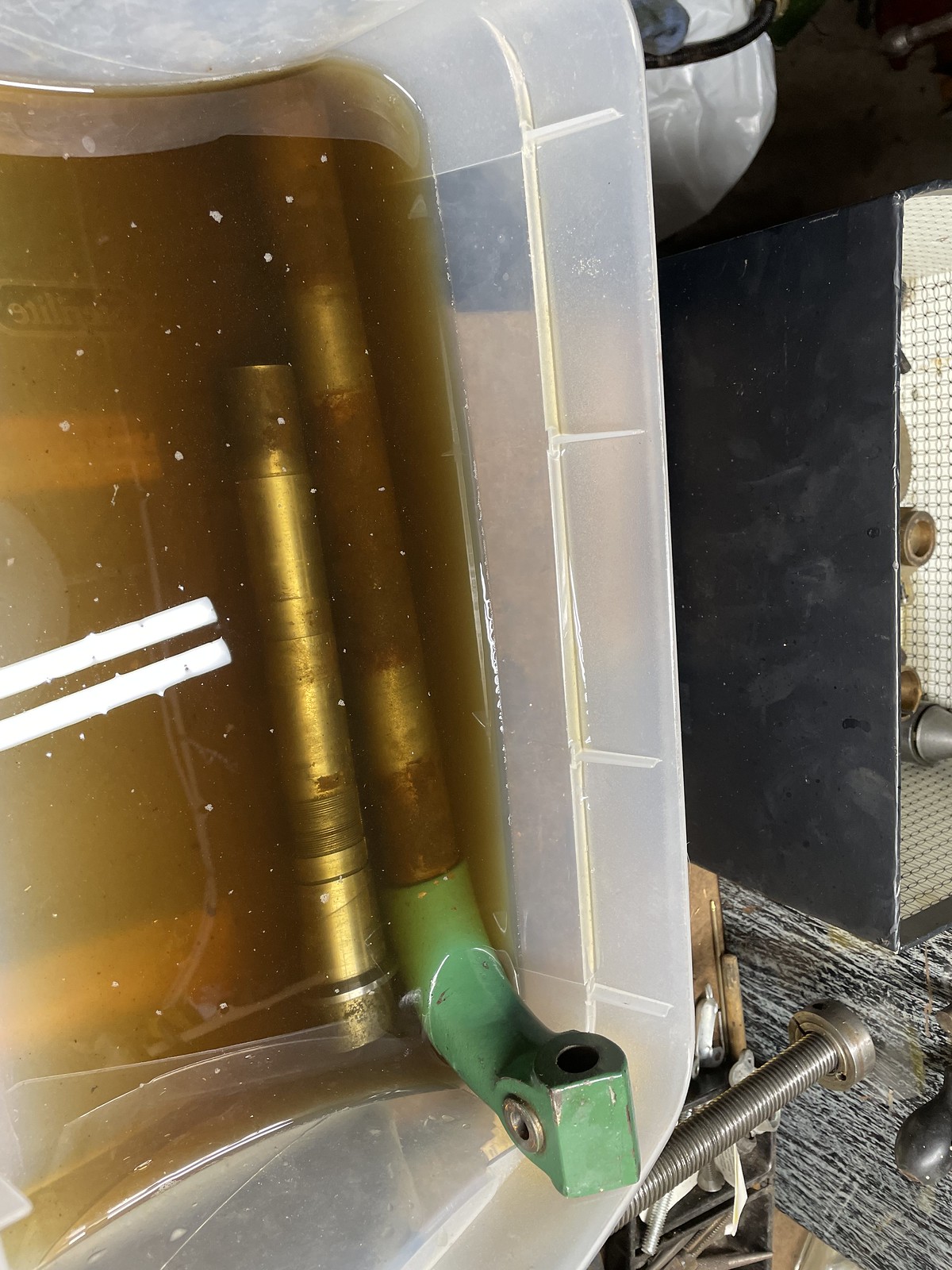

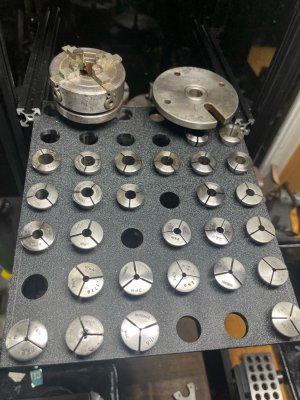

And here it is in place. Now to find the right height for the counter shaft assembly, which is off of some equally old Craftsman (not sure what, I will have to ask my friend Brian, as he is an expert on all things C-man.) The counter shaft is going to be raised higher than I like, but as the machine was originally set up for some sort of overhead line shaft I don't have much choice. Of course, I am going to have to make a bushing for the cone pulley that mounts on it, because nothing is ever simple:

Oh well, that will be tomorrows project.