Very close!

Thanks.

Daryl

MN

The Di-Acro or Rotex limits you by the station sizes. I don't have one but have used a few different models. The FA Robbins has lots of potential and the price is right, especially with the make offer invite, plus it fills the "Beast" qualifications. I'm not sure what the 15-20 ton comment is about, they're usually rated specific to tonage. Without a photo shot of the front it's difficult to tell if it can be set up for more than single station processes.

Here's a link to the standard arbor presses http://www.dakecorp.com/products/arbor-presses

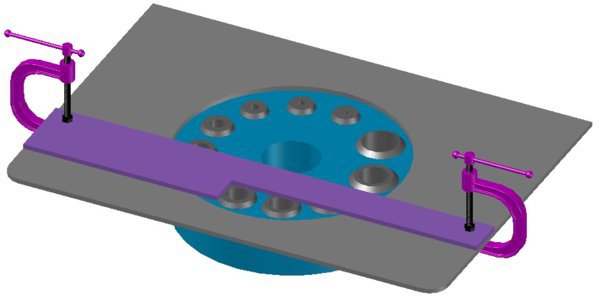

I recomment the ratchet or compound type if you choose this direction. I have a 3-ton import single lever that I inherited that takes a cheater to get much action. My recommendation would be the Robbins or similar model especially if you apply tool and die machining to get the **How did you do that** questions. Plus, it's nice to hit the lever and get the single hit with the Beasty Speed. I have a 7.5 ton Benchmaster set up to punch 4 holes (pretty simple) which I haven't used in a decade that I would offer up if you were closer. I'm sure there are presses at good prices, much closer to you. If the press has been abused it's usually scrap metal because a repair usually involves the frame.

Russ