- Joined

- Feb 17, 2013

- Messages

- 4,407

What Adam talked about was Ikea "Billy" bookshelf, https://www.ikea.com/us/en/p/billy-bookcase-white-50263838/ that he uses with glass doors for display cabinets. The long row of them pretty much fill up one wall of his shop.

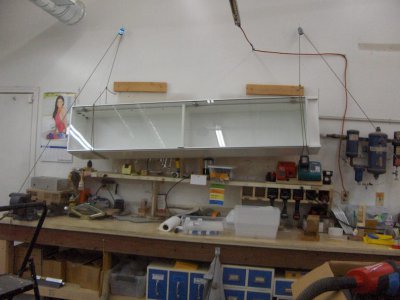

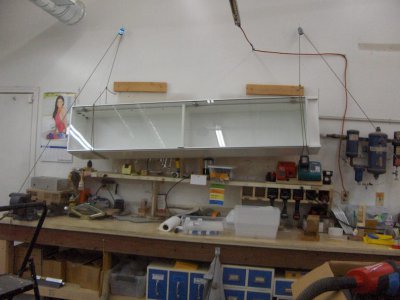

I bought one, left out the shelves, got a frameless glass door, and hung the shelf sideways (door hinged on the top edge) above my workbench. Added a 12 volt LED strip for illumination. Keeps dust off a whole bunch of "tchotchkes." First photo is my method of hoisting it into place "solo." Second photo shows the door propped open and the lighting.

I bought one, left out the shelves, got a frameless glass door, and hung the shelf sideways (door hinged on the top edge) above my workbench. Added a 12 volt LED strip for illumination. Keeps dust off a whole bunch of "tchotchkes." First photo is my method of hoisting it into place "solo." Second photo shows the door propped open and the lighting.

Last edited: