-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quarantine Projects!

- Thread starter Weldo

- Start date

What's "engineered fuel"? Not heard of that before.

I hadn't either. They had it in the aisle with the wackers and mowers. I think the idea is that it doesn't go bad as fast as gas and clog things up. I've only been using it for a year or so, but the Wacker starts easier and seems to run better than the gas I mixed. I had been using ethanol free to make sure the ethanol wasn't causing any problems. This stuff just seems to work better. Perhaps it's partly that I only run it once a week or so in the summer.

- Joined

- Jan 2, 2019

- Messages

- 6,573

<snip>

As far as the weed whackers, I too have 3 and none of them run properly! Two of them only run on half choke, and thus only give you about half power, and the other one, despite being super clean and only 2 years old, will not start at all! What the hell, ya know?!

As a guy that used to run a small engine shop I can tell you what probably happened. Everyone knows to check for compression but two-strokes need a good lower end seal to draw the fuel/air charge into the engine. More often than you would think the crank seals go bad while sitting, might be ethanol in the gas, might just be crappy seals but regardless the result is you can do whatever you like to the carb or spark plug but no amount of pulling will get them to start.

Since I had to quickly diagnose these things I developed a protocol.

1. pull the starter rope to make sure there's compression and the cylinder isn't stuck.

2. drain the old fuel

3. check for spark, install new plug since I bought them by the gross.

4. remove air cleaner and shoot a little carb cleaner in.

5. give it another pull and see if it fires.

6. if it fires put fresh mix gas in and see if it will run

7. if it only runs on choke clean the carb and maybe put a kit in

8. if none of the above works scrap it out unless it's a high end unit that is worth fixing

The problem with these things is the only way to check crank seals is pulling it apart and fitting blanks to seal off intake and exhaust ports then pressure check. Unless it's a high end unit and you already have the sealing blanks this is about two hours more labor than a replacement tool will cost. if you can get it running you can shoot a little carb cleaner at the ends of the crank to see if it makes it run better but that's really hit or miss. Honestly, if you get to step 6 and you're not trimming the chance of it ever working is pretty small. Sometimes replacing the primer bulb or fuel lines will do the trick but you can see that problem.

Reality is I've already spent more time typing this up than it takes me to troubleshoot a cheap weedwhipper

My honest suggestion is when one of these things doesn't start you really have two options. If you have a huge yard and need to trim every week invest in a good straight shaft trimmer and only use ethanol free gas + drain it whenever you won't need it for a month. Or, if you're smart like me get an electric one. The corded units are super cheap and the battery powered ones are good enough now to replace gas powered for most homeowners. Bonus points for getting the one that takes the same batteries as your drills and impacts.

Cheers,

John

- Joined

- Jan 2, 2019

- Messages

- 6,573

My problem with whackers is I don't need it as often as you so they sit and the carbs clog. I have a buddy who lives in the mountains and runs his all the time because of fire danger and seems to have no problems.

I can't tell you how many guys brought me their trimmers to have the "carb cleaned", rarely is that the problem. Your buddy probably has a good model to begin with and like you say, runs it all the time. Yes, ethanol gas can mess up a carb in a hurry but it also eats crank seals which is where the real problem usually is. I know, super frustrating for someone with a two-year-old machine but unless you rebuild the carb yourself ~$10 for the kit, you're $75 bucks into fixing a $60 tool at most repair shops.

Cheers,

John

- Joined

- Feb 9, 2017

- Messages

- 5,265

My dad had probably 5 dead whackers. They were all given to him by folks in the park he lives in and not a single one were same make or model. One was brand new looking and I tried getting it going and besides the passages in the carb being incredibly tiny the carb parts were turned to goo. The whole gas whacker thing just seems like a complete boondoggle so I bailed long ago. I appreciate your confirmation of my suspicions John.

- Joined

- Sep 7, 2019

- Messages

- 674

Everyone knows to check for compression but two-strokes need a good lower end seal to draw the fuel/air charge into the engine. More often than you would think the crank seals go bad while sitting

You know that makes a lot of sense! It's great to talk to someone with expertise!

I've been tinkering with an old Craftsman trimmer for a long time now, partly out of necessity and partly out of a weird combo of stubbornness and fascination. I did get it to run, but only on half choke. So I figure when it's not on choke it must be way too lean, right, since I block off half the air with the choke and it runs almost normal. So I bought a kit and rebuilt the carb, which was pretty darn clean inside anyways. The rebuild didn't make a lick of difference and it really had me stumped. I didn't replace the plug but did take it out and clean it up.

That trimmer is configured such that the crankcase is sealed up by the plastic housing that serves as the main enclosure/heat shield around the muffler. It did have it off at one time. If I recall there was a paper gasket. Maybe a bead of silicone could be applied to the mating surfaces?

- Joined

- Sep 7, 2019

- Messages

- 674

I've started another project!

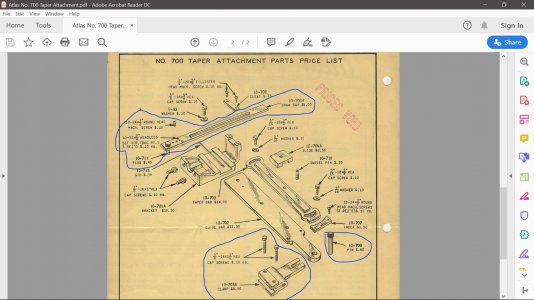

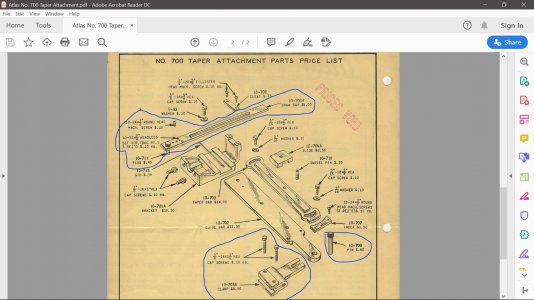

I'm gonna try to finally get my old taper attachment bolted to my machine. I need a few parts, namely the clamp and the draw bar.

The parts I need to make are circled in blue.

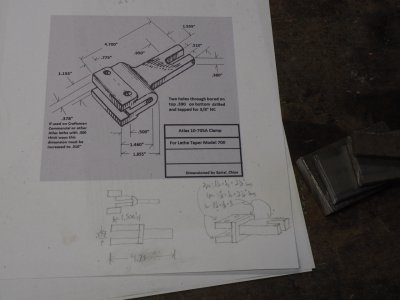

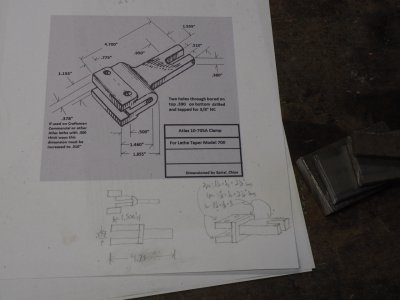

Big shout out to @wa5cab and Spiral_Chips for making available some dimensioned drawing of these parts!

This is the drawing as dimensioned. I'm gonna try to weld together a composite piece like the pencil sketch near the bottom.

The original piece clamps to the flat ways of the Atlas lathe. It has a step that acts as a depth stop. In my case the two bolts will act as the depth stop. I think It'll work.

For the slot in the end, I'm not sure if I'll attempt to slot it with an end mill on the lathe with the milling attachment or just drill a hole and cut the slot with an angle grinder. It'll depend on if I can hold the piece in the milling vise, it's pretty limited in work holding ability and rigidity.

I'm gonna try to finally get my old taper attachment bolted to my machine. I need a few parts, namely the clamp and the draw bar.

The parts I need to make are circled in blue.

Big shout out to @wa5cab and Spiral_Chips for making available some dimensioned drawing of these parts!

This is the drawing as dimensioned. I'm gonna try to weld together a composite piece like the pencil sketch near the bottom.

The original piece clamps to the flat ways of the Atlas lathe. It has a step that acts as a depth stop. In my case the two bolts will act as the depth stop. I think It'll work.

For the slot in the end, I'm not sure if I'll attempt to slot it with an end mill on the lathe with the milling attachment or just drill a hole and cut the slot with an angle grinder. It'll depend on if I can hold the piece in the milling vise, it's pretty limited in work holding ability and rigidity.

- Joined

- Jan 2, 2019

- Messages

- 6,573

You know that makes a lot of sense! It's great to talk to someone with expertise!

I've been tinkering with an old Craftsman trimmer for a long time now, partly out of necessity and partly out of a weird combo of stubbornness and fascination. I did get it to run, but only on half choke. So I figure when it's not on choke it must be way too lean, right, since I block off half the air with the choke and it runs almost normal. So I bought a kit and rebuilt the carb, which was pretty darn clean inside anyways. The rebuild didn't make a lick of difference and it really had me stumped. I didn't replace the plug but did take it out and clean it up.

That trimmer is configured such that the crankcase is sealed up by the plastic housing that serves as the main enclosure/heat shield around the muffler. It did have it off at one time. If I recall there was a paper gasket. Maybe a bead of silicone could be applied to the mating surfaces?

Have at it....

John

What kind of plastic line is that? Was it a kit?

I need to run some lines for my shop too.

I used ProPEX left over from some heating and plumbing projects. It’s Uponor’s version of PEX, which uses plastic rings on the ends and an expansion tool stretches them so you can skip in a fitting; the pipe and ring shrink down on a few seconds. I like it for plumbing and so far it seems to work well for air too.

Today’s project was painting a wall and adding some storage bins. Then the kids started working on a mural for the wall too.