- Joined

- Mar 26, 2014

- Messages

- 1,500

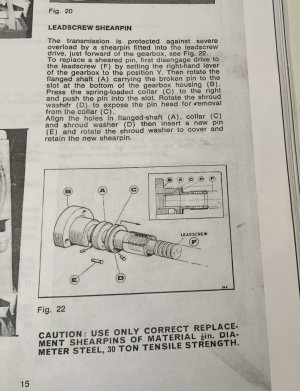

If the Colchester is similar to a Harrison, it may have a sleeve that slides to engage the lead screw at the headstock. Or the change gears are not engaged?. Or like you mentioned a broken shear pin.

Nice lathe.

Cheers

Martin

Nice lathe.

Cheers

Martin