- Joined

- Sep 29, 2017

- Messages

- 2,251

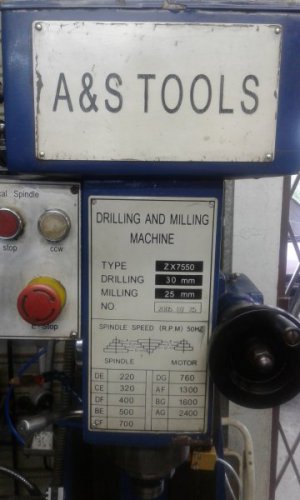

Quick question. My mill/drill spindle rumbles quite a lot at certain speeds but not always. Is it definitely the spindle bearings or could it be something else also. Just want some info before I start stripping. I had a smaller type mill/drill before with the same problem and replaced the bearings with no improvement as I recall. That's why I am asking.

Michael

Michael