- Joined

- Dec 3, 2017

- Messages

- 1,911

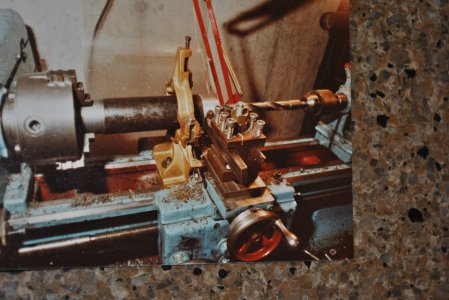

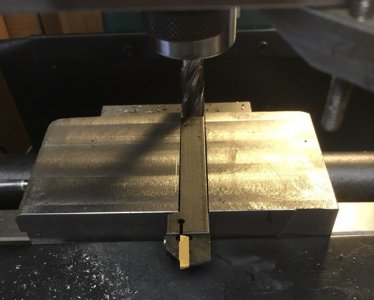

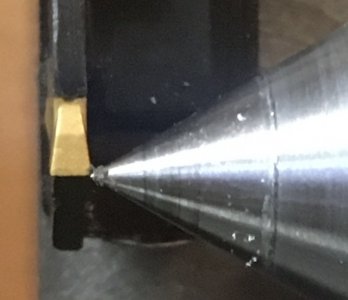

Working on this now. My last project left me with a couple good size chunks of cast iron. I milled a ledge, so that it'll always mount perpendicular to the ways. Still have some cutting, drilling, milling and tapping before it's done.

Attachments

-

D3B2CEAA-629E-4C88-881F-20587EDF73F6.jpeg73 KB · Views: 75

D3B2CEAA-629E-4C88-881F-20587EDF73F6.jpeg73 KB · Views: 75 -

2E2CBB88-5EF6-4822-AF40-2D94A34F0FC1.jpeg82.3 KB · Views: 53

2E2CBB88-5EF6-4822-AF40-2D94A34F0FC1.jpeg82.3 KB · Views: 53 -

B40D82DA-99E5-4FB6-9272-61DF45FFF57D.jpeg84.3 KB · Views: 42

B40D82DA-99E5-4FB6-9272-61DF45FFF57D.jpeg84.3 KB · Views: 42 -

BAC1AA23-D9AC-4216-8D58-6C588419A60A.jpeg63.4 KB · Views: 45

BAC1AA23-D9AC-4216-8D58-6C588419A60A.jpeg63.4 KB · Views: 45 -

8419C94D-4ED6-4F1A-BDD4-93B3C2219C73.jpeg80.7 KB · Views: 70

8419C94D-4ED6-4F1A-BDD4-93B3C2219C73.jpeg80.7 KB · Views: 70