- Joined

- Dec 3, 2017

- Messages

- 1,911

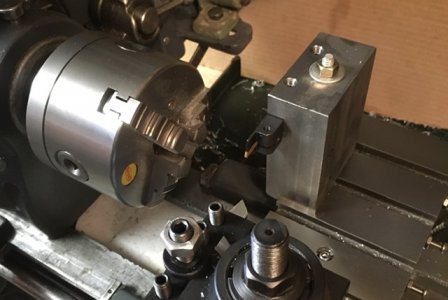

Ok that's what I was thinking, but giving dimensions is great. Was the central hold down bolt hole slotted or purposely oversized? Seems like it would have to be to keep from bending the stud when it was tightened. I guess .100 may not be enough to affect it? I'm curious cause it seems like a great way to get some adjustment without any fuss.