-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Removing a Jacobs drill chuck from an Atlas Drill Press

- Thread starter cvuxton

- Start date

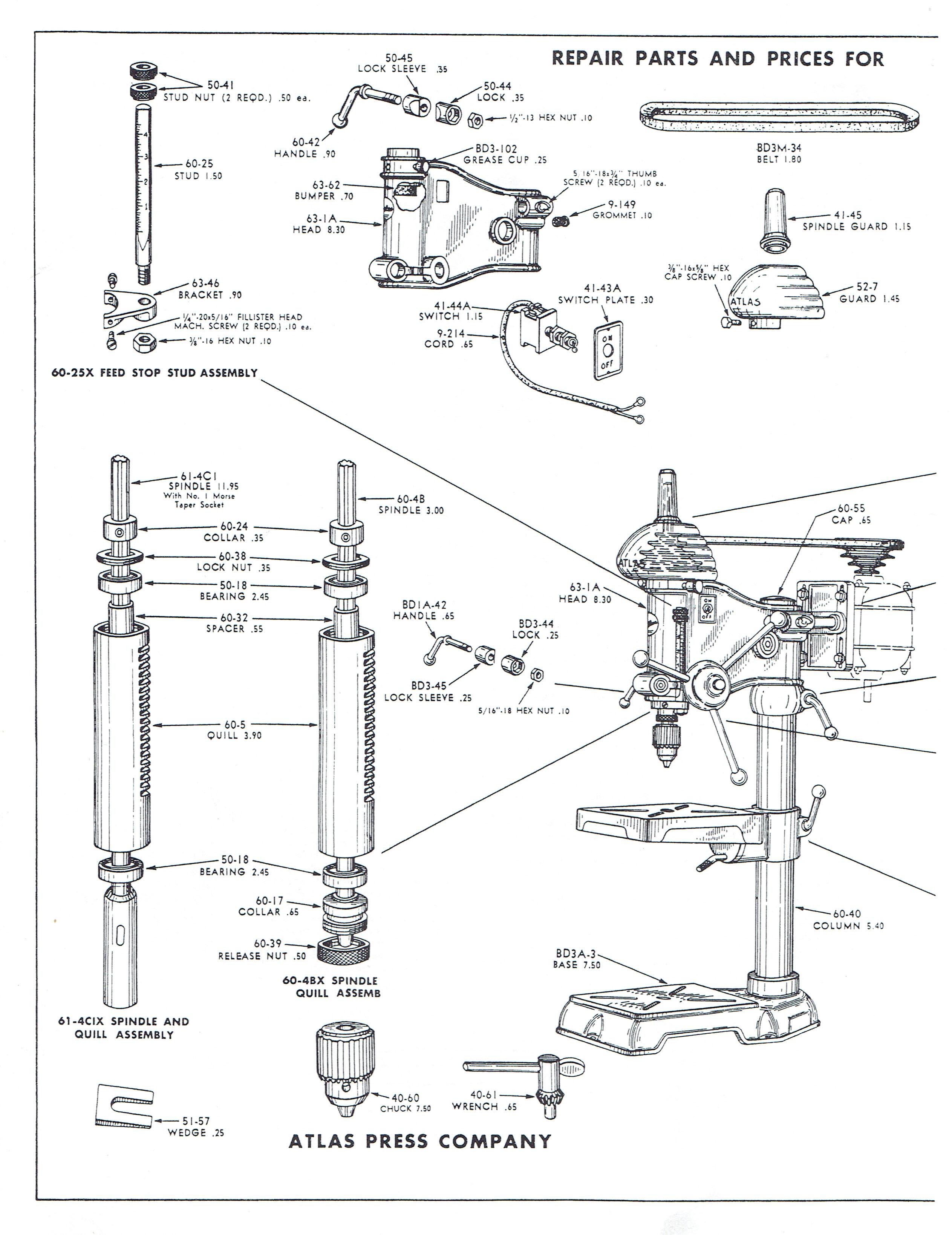

The wedges might have to fit in the narrow groove of the spindle just above the chuck to work. The wedges need to be just the right dimensions to hold in the small groove, not pushing against the housing. This picture comes from this article

http://www.instructables.com/id/Wedges-for-Drill-Chuck-Removal/

Wedges still won't work? Is there a through hole in the chuck so that a gear puller can push against the arbor? If so then can a gear puller be used to pull the chuck off the spindle like you would be removing a gear.

http://www.instructables.com/id/Wedges-for-Drill-Chuck-Removal/

Wedges still won't work? Is there a through hole in the chuck so that a gear puller can push against the arbor? If so then can a gear puller be used to pull the chuck off the spindle like you would be removing a gear.

Last edited:

4

4GSR

Forum Guest

Register Today

Tozguy is on the right track. I would take the spindle apart, tear down as far as you can heait. Chuck it up in the lathe, run a steady rest on the lower bearing. Then drill a 1/2" hole thru the ID of the chuck body to the spindle. Will not hurt if you drill into the spindle a little. Just don't go too far into the spindle. Set up in a hydraulic press, drop a 1/2" steel rod into the bore of the chuck, hand tighten the jaws around the steel rod. The steel rod just needs to stick up out of the chuck about 1/4 to 1/2" and no more. Press on it and hope the spindle pops loose. If not proceed to take apart the chuck. If you're not intending to save the chuck start turning to OD of the chuck body off of the spindle until you get to an diameter and it pops off by hand. OR if you want to try to save the chuck, with the spindle in the press, apply heat and press until it releases. If heat doesn't work, well start turning the OD of the chuck body until you get it to release.

Last edited by a moderator:

4

4GSR

Forum Guest

Register Today

One last ditch effort you could try and I don't recommend it, and I've done it before. IS take a big crescent wrench, wedge it between the spindle and chuck body, and give the wrench a sharp blow acting as a fulcrum bar and see if that will knock it off. I did this to salvage a Albrecht chuck off an old drill press that was being scrapped. I'm sure the spindle was bent after that exercise! And I still have that chuck and it still runs dead true!

- Joined

- Feb 7, 2011

- Messages

- 5,039

I would download the proper manual, It tells how to take the quill out . and how to remove the spindle. once you have the spindle out if there is not a hole in the base of the chuck drill one and drive the spindle out of the chuck with a drift pin.

Well, it looks like taking the spindle out and seeing if that setscrew is loose is a start. I like this thing, if for no other reason than someone painted it baby blue, like my favorite car of all time, a 1960 Ford Falcon. can see where someone tried the BFH route too, which is probably the reason its hard to open and close. Thanks to all for the suggestions, and the page from the manual showing all the parts. I can't get to it before next week so I'll report back after that.

OK...thats messed up. That knurled collar should be resting against the top of the chuck body. There is just a short male taper that fits into the top of the chuck. The collar (#60-39 in the manual) should be tightened against the chuck body and the taper should pop loose. If you fit a spacer of some sort between the collar and the chuck and tighten the collar into it does everything just continue to drop lower? (I guess the collar is called the release nut in the manual)Well...no joy no matter what. I ran the spindle down and there's no slot. I tried unscrewing the two collars above the chuck, after tapping the chuck back up. Nope. I locked the spindle and the shaft still moved down. As you can see from the pictures, someone has tried before, with a big hammer.

View attachment 244096 So now, seeing as the shaft wants to come down can it be tapped all the way out and then try to persuade the darn thing to release. I've heard of applying heat, then Kroll or some such stuff, and then freeze.

The manual's explanation doesn't seem to do it.

Oh, about additional numbers, you can see in the photo 6A 33T.

- Joined

- Feb 1, 2015

- Messages

- 9,621

From your photo and the manual parts list, it appears that the knurled ring is a retaining nut for the chuck arbor. I seem to remember some drill presses/mills where the Morse taper had a ring that was held captive on that fashion and which in turn prevented the arbor from coming loose during use. If you can loosen the set screw in the knurled ring, You can try to loosen the ring using a strap wrench, padded vise grips, etc.

As you turn the ring, it should lower and the arbor should drop with it, possibly with a little persuasion. A U shaped shim placed between the chuck and the release nut combined with unscrewing the release nut should either pop the Morse taper or the chuck from the Jacobs taper.

edit

Looking at the drawing more closely, it appears that the spindle has an integral Jacobs taper and the function of the release nut is to push the chuck off the taper. What Chuck K. posted above should work.

It is possible that the PO had problems keeping the chuck on the spindle and glued it with superglue or epoxy. In that case, heat would have to be used as well. Heating to 250-300ºF should be OK and will soften eiter of those adhesives, permitting removal.

As you turn the ring, it should lower and the arbor should drop with it, possibly with a little persuasion. A U shaped shim placed between the chuck and the release nut combined with unscrewing the release nut should either pop the Morse taper or the chuck from the Jacobs taper.

edit

Looking at the drawing more closely, it appears that the spindle has an integral Jacobs taper and the function of the release nut is to push the chuck off the taper. What Chuck K. posted above should work.

It is possible that the PO had problems keeping the chuck on the spindle and glued it with superglue or epoxy. In that case, heat would have to be used as well. Heating to 250-300ºF should be OK and will soften eiter of those adhesives, permitting removal.

Last edited:

- Joined

- Jan 14, 2016

- Messages

- 86

I have that same style DP the reason for posting the parts diagram. The knureld nut is as others have deterimind the way to remove the chuck no wedges needed. The chuck should fit very close to the nut on a short integral JT since it slips down there has to be something loose on the spindle shaft. Who knows until torn down if someone beat on the top of the shaft, bearings and everthing could have been screwed up. Hope that is not the case. I tore mine down for other reasons but didn't remove the spindle from the quill as it was not necessary. The removal and replae ment was pretty easy so I wouldn't hestate if I were you.

- Joined

- Apr 30, 2015

- Messages

- 11,328

I'd use heat also, and some persuasion

Mark

Mark