Hey,

I've been a long time lurker since I've always been able to find what I was looking for with the search and not much to contribute beyond what others already had - but I have a problem I'm looking for some ideas on solving I couldn't really find already addressed.

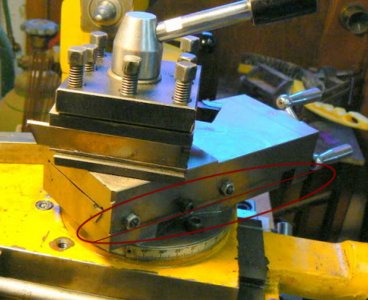

I have a Grizzly 9x19 and I thought I was on my way to getting this thing dialed in as much as the machine is capable in terms of rigidity and I just found another issue. I already created a new compound clamping ring for it to use the 4 bolt points instead of 2, and that helped a lot. But when pushing on the QCTP I noticed there was about 4 thous of play in either direction. I started looking to see if it was coming from and I could actually see the movement (thanks to the lube moving) occurring, and it is in the compound slide, between the compound slide "lower half" (the fixed section with the gibs and gib adjustment screws) and the "upper half" (the section that slides). Those two halves should obviously not show any separation and just mate tightly together. So I thought maybe the gibs loosened up some, but they were still nice and snug. Just to test I tightened them as much as I could and it had no effect.

I am going to disassemble it to inspect for any issues, but I have a couple parts I need to finish first. Until then, I'm wondering if anyone has any tips on how to resolve this (maybe polishing the mating surfaces?) or what to look for.

Once I get that squared away I can start address another mystery that is occurring where my larger parts are coming out with a very slight taper even though the tailstock is zero'd, part centered to zero, and the TDI reads zero up and down the ways.

Thanks!

-J

I've been a long time lurker since I've always been able to find what I was looking for with the search and not much to contribute beyond what others already had - but I have a problem I'm looking for some ideas on solving I couldn't really find already addressed.

I have a Grizzly 9x19 and I thought I was on my way to getting this thing dialed in as much as the machine is capable in terms of rigidity and I just found another issue. I already created a new compound clamping ring for it to use the 4 bolt points instead of 2, and that helped a lot. But when pushing on the QCTP I noticed there was about 4 thous of play in either direction. I started looking to see if it was coming from and I could actually see the movement (thanks to the lube moving) occurring, and it is in the compound slide, between the compound slide "lower half" (the fixed section with the gibs and gib adjustment screws) and the "upper half" (the section that slides). Those two halves should obviously not show any separation and just mate tightly together. So I thought maybe the gibs loosened up some, but they were still nice and snug. Just to test I tightened them as much as I could and it had no effect.

I am going to disassemble it to inspect for any issues, but I have a couple parts I need to finish first. Until then, I'm wondering if anyone has any tips on how to resolve this (maybe polishing the mating surfaces?) or what to look for.

Once I get that squared away I can start address another mystery that is occurring where my larger parts are coming out with a very slight taper even though the tailstock is zero'd, part centered to zero, and the TDI reads zero up and down the ways.

Thanks!

-J