- Joined

- Feb 15, 2018

- Messages

- 18

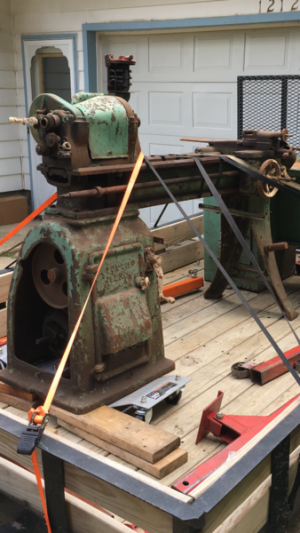

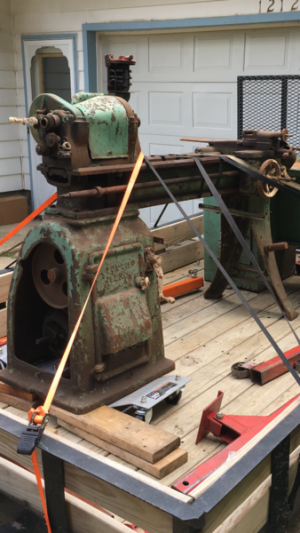

I picked up a 1936 sounthbend 13” lathe from a garage sale recently. It is missing a few parts. Who would be a good source to get parts from? My lathe came from a school and is a basic machine. It does not have a quick change gear originally but it came with one. I believe the previous owner was converting it. Will it be possible to change and what drive screw would i need? Thank you for any help. I added a picture of my lathe.