Good that you are solving your own issues. Mine was hooked up backward at first also. Must be some kind of Murphy's law in play here

if getting that shaft straightened don't work, let us know.

Ya, previous owner had cut the wires off the terminals, which left simple wire color fossils, which I used but apparently one of us had the red/white wired differently. I accepted defeat when I fired up the $900 lathe for the first time and the spindle didn't want to work, I assumed there was an issue to begin with. But an sos call to my father, a machinist of 30yrs, pointed me into troubleshooting mode. Lifting the cover off the headstock, I found that the servo shift seemed not to be shifting, and the hydraulic pump was gurgling oil in the bottom on the headstock. I cracked the line going to the servo shift valve body, and cautiously ducked and covered with a rag while shifting into the "oscillation mode", found that no oil was being sent to the valve body... The pump appeared to be out the return, and in the supply... Backwards red/white... Ehh, happens

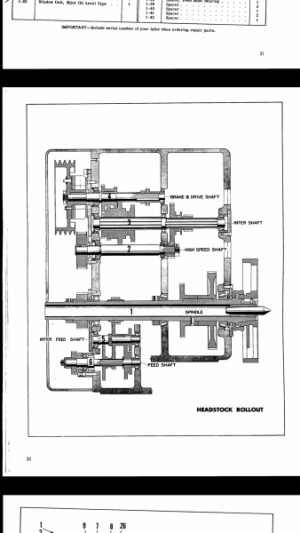

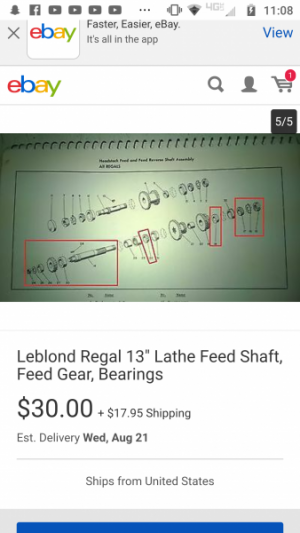

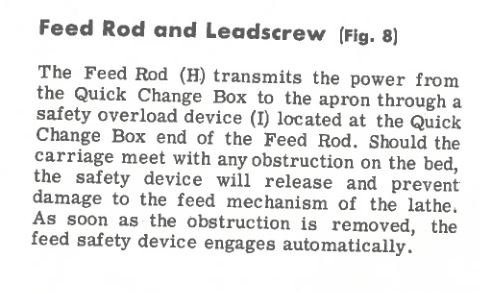

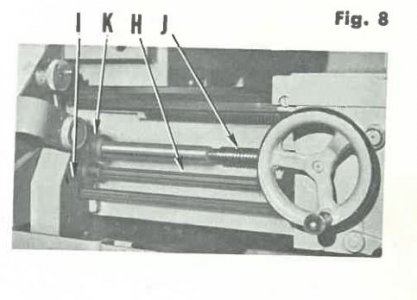

As far as the bent shaft... Ehh, that's a bummer, hoping to somehow find a replacement shaft. Originally had noticed that the two position "P-F" feed shift handle seemed to be inoperable , and wouldn't shift in/out of gear. With the headstock apart, and 20mins of staring, poking, and prying it appears the shifting gears are bound up on the splined section of the shaft, assuming due to the bent shaft. Due to the bent shaft, the machine does make gear growls , as the wobble of the gear on that shaft binds with the gear it drives. I would like to remove the shaft, to possibly make a repair, just stinks I will loose all carrage and cross slide feeds until replaced

The servo shift is cool, and my father truly impressed by it's 50yr old design. So, it works, mostly, onto the general maintenance, oils, filter, cleaning and fresh paint. Hopefully come up with someway to replace this shaft, as threading was a large portion of the reason for purchasing this machine

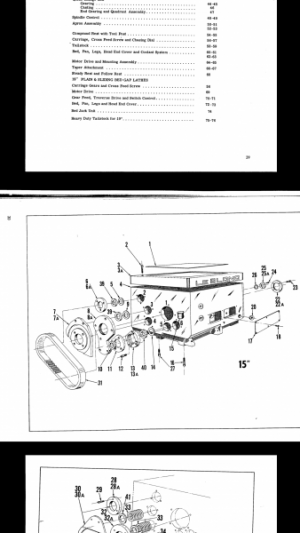

What is the proper terminology for this "P-E" , two position, threading feed, Shaft?

It appears to have no relationship with the "servoshift" aspect of the machine, can I assume manual shift machines of a broad year range would use the same shaft?