- Joined

- Jun 7, 2016

- Messages

- 361

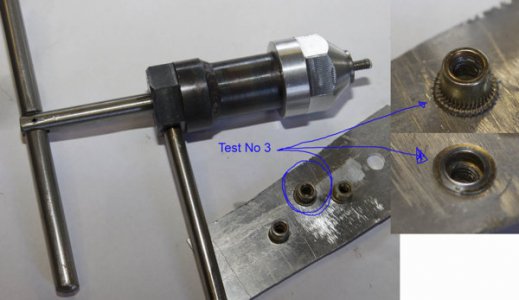

I am sure your tool was cheaper and may well work better than what I have constructed - we all make choices.There is nothing like making something for your own use.

I myself just bought one of these from HF and picked up some different sized inserts on Amazon.

https://www.harborfreight.com/45-piece-threaded-insert-riveter-kit-1210.html

Worked great. I spent more on the inserts than I did for the tool.

Used them when I put together my sand blast cabinet instead of the bolts and nuts that came with it.