- Joined

- Oct 31, 2016

- Messages

- 2,649

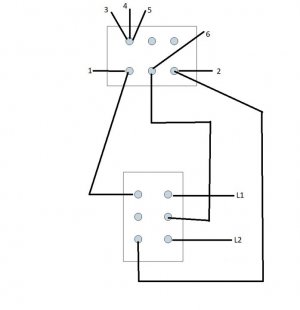

A picture of the drum switch would also help to decipher the wire colors coming from the switch. Also would help to remove the unused wires. The white, black and green wires that look to be from a cut off 110 volt cable and there appear to be two black wires that have some type of terminal on the end that don't connect to anything. That would clear up things up and give a better visual of the terminal block. Another thing that would help is labeling which wire numbers from the motor go to which terminal.

I looked at the wiring on my RF 30 clone. For 220 volt wiring there are 3 wires connected together, wire numbers 3,4,& 5. Your wiring also has 3 wires connected together but I can't see the numbers. For forward L1 from the switch connects to wire 1 and L2 from the switch connects to wires 2 & 6. For reverse wire 1 and wire 2 are swapped on the wiring diagram on my motor. I am interested in this because I have 220 in my garage and am thinking about converting my mill/drill to run on 220 with a reversing drum switch. I'll do a sketch post it.

I looked at the wiring on my RF 30 clone. For 220 volt wiring there are 3 wires connected together, wire numbers 3,4,& 5. Your wiring also has 3 wires connected together but I can't see the numbers. For forward L1 from the switch connects to wire 1 and L2 from the switch connects to wires 2 & 6. For reverse wire 1 and wire 2 are swapped on the wiring diagram on my motor. I am interested in this because I have 220 in my garage and am thinking about converting my mill/drill to run on 220 with a reversing drum switch. I'll do a sketch post it.

Last edited: