You will have better success with high speed steel. Ditch the carbide on a smaller lathe. There is an excellent article on this site on how to grind a lathe tool. You are fighting a loosing battle with carbide in a light duty lathe.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rough Finish on 1" Hot Rolled Steel

- Thread starter JRT

- Start date

- Joined

- Dec 21, 2018

- Messages

- 1,829

Lots of good recommendations. I also like 12L14. Plenty strong enough for everything I do. I use O-1 tool steel to make cutters and buy square HSS blanks online. Easy to grind. You don't have to get precisely the recommended angles for it to work OK. I'd stick with HSS on a small lathe. There is satisfaction when I make a tool and it works. I've got some inserted tools and they work OK on my more powerful lathe. HSS tools that I have made: threading, chamfer, combination in & out chamfer, Inside & outside radius, boring bars, fly cutters, reamers. The great thing about HSS tooling is it is a lot less $ to sharpen than buying new inserts.

For polishing that gummy, cheap steel, buy a few shop rolls of abrasives.

For polishing that gummy, cheap steel, buy a few shop rolls of abrasives.

- Joined

- Oct 11, 2016

- Messages

- 3,871

Don't fret about how strong 12L14 is. It is stronger than 1018 hot rolled. It is a great steel to start with!

This thread might help you get a better finish on gummy steels.

This thread might help you get a better finish on gummy steels.

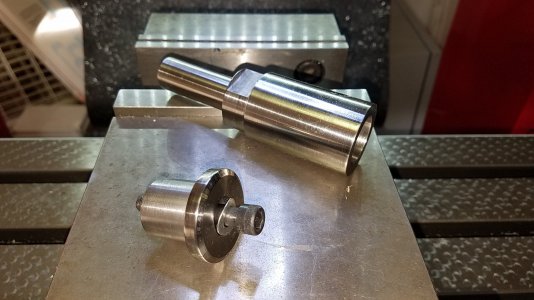

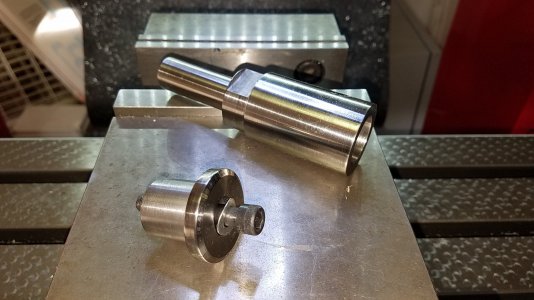

I agree about HSS vs carbide tools on light duty lathes to a point. I was taught a long time ago how to grind tools in the gunsmithing classes I took. I have some HSS tools that I made specifically to give a better finish on 1018 but I had never gotten a "good" finish on 1018. The pictures I posted don't show the finish I got all that well. I use carbide on 12L14 all the time. I've been making parts for the guns on the battleship USS Texas from 12L14 and recently made over two dozen 1/2" x 1" Fillister head screws for the 5" guns from free machining brass. That was fun! LOTS of work but fun.

I have not tried to double the feed rate. Maybe I should. I just assumed that the faster the lead screw turned, it would leave more raised “strings” since I’m not running the RPM too fast. -John

You're feed rate is attached by gears to the spindle/chuck. If you set your feed rate at 0.002, that's two thousandths per revolution of your work piece. It's directly tied to the turning speed. You can think of it as cutting a very, very, rediculously fine thread. It doesn't matter the speed, whatever speed you're at, you get the same advance on the material, and the same size of the chip, no matter what RPM the spindle is set to. The three variables you're looking at here are the spindle speed, the depth of cut, and the feed rate. Up to the point you run out of horsepower or work piece rigidity, consider all three to be separate variables, independent of one another.

Some mild steel just doesn't cut well. Or it does cut well, but it leaves that finish where it tears at the edge. A lathe file, emery cloth, scotch brite, and similar items are your friend if you're going to work with mild steel. It takes some practice and a little bit of judgement that you can only learn, but can't really be taught, but if you leave half a thousandth to a couple of thousandths, (more if it's real bad), you can file, sand, polish down to dimension in a pretty quick process. Cover the ways and work slow at first. You'll find that the first bit (the worst of the roughness) disappears quite quickly, but as soon as the material begins to smooth, there's more bearing surface, less edges for the abrasive to get a hold of, and the process slows right down to where you've got pretty good control to hit a very tight dimension. Exception being the file. That keeps right on cutting. The abrasives are what slows down as the finish improves. Just measure often and in multiple places, and spend a little extra time on the "big" spots, and you can hit very tight dimensions quickly and easily that way. Maybe not on the first try, but it's a relatively quick learning curve compared to some other things you run into in this hobby.

Depending on what materials you can get your hands on (or justify), often finding a different material might be the most practical solution. But if mild steel comes easily, or cost/benefit analysis says that you can spend some extra time and don't need extended properties beyond mild steel, it's an annoying, yet quick and easy workaround with very low overhead, and will yield good parts. Start by playing with the speed, feed rate, and depth of cut, as well as your cutting tool. Some steels will cut very well when dialed in. Some steels just flat out won't, and require some polishing no matter what you do.. But even if the material just straight up won't cut nicely, the better it comes out, the quicker the sanding process works out. It's not really a hack to have to resort to such things. If you're cutting 1018 for example, there's no shame in falling back to plan B.

The point of my exercise was not to polish 1018. It was to machine to tolerance with an acceptable finish for the intended purpose. In the past I've done all of the fixes for smoothing 1018 and until now my specially ground HSS bits did a decent job. I was trying to get a 12L14-like finish with the 1018. Since the fit between the saw blade, the cap and the body of the arbor were critical dimensions they all had to be machined and not hand finished.

Just to clarify, this was an EXPERIMENT to see what I could accomplish with 1018. I'm not a beginner. I wasn't asking how to do this; just trying to contribute what I did to the discussion and how it turned out when done to a set of parameters that I had set for the experiment. Those parameters included no hand finishing for the critical parts fits. Yes, I could have used a different material. That would not have been an experiment. Had I chosen to use 12L14 there would have been nothing learned. The bearing surface between the cap and the body is only about .800" long (1.000" diameter) and any taper or irregularities introduced by hand finishing would have likely made the parts unusable. If the results had been unacceptable I would have made another from 12L14 which I had on hand.

Just to clarify, this was an EXPERIMENT to see what I could accomplish with 1018. I'm not a beginner. I wasn't asking how to do this; just trying to contribute what I did to the discussion and how it turned out when done to a set of parameters that I had set for the experiment. Those parameters included no hand finishing for the critical parts fits. Yes, I could have used a different material. That would not have been an experiment. Had I chosen to use 12L14 there would have been nothing learned. The bearing surface between the cap and the body is only about .800" long (1.000" diameter) and any taper or irregularities introduced by hand finishing would have likely made the parts unusable. If the results had been unacceptable I would have made another from 12L14 which I had on hand.

Last edited:

All great info here guys and I appreciate it all.

Nice slitting saw arbor David! I want to use a slitting saw soon so that may be close on my list of to-dos!

I made a list of all of these steels as that's another area I'm not well versed in yet. So far I've really mostly used 6061 aluminum, cold rolled steel and brass on my lathe and mill. Mostly parts to fix other machines. I just made some brass gibs for a fixture mill I got but will probably have to make them from steel at some point. I made some chuck keys for my lathe from some W1 and had them hardened a little because I'm excessive I guess, lol. Point is, I know a little but really need and want to learn more so I'm really happy to log on this morning and see all of your replies. Very helpful! I really need to get up on my lathe/mill feeds and speed knowledge too and am working on that now. -John

Nice slitting saw arbor David! I want to use a slitting saw soon so that may be close on my list of to-dos!

I made a list of all of these steels as that's another area I'm not well versed in yet. So far I've really mostly used 6061 aluminum, cold rolled steel and brass on my lathe and mill. Mostly parts to fix other machines. I just made some brass gibs for a fixture mill I got but will probably have to make them from steel at some point. I made some chuck keys for my lathe from some W1 and had them hardened a little because I'm excessive I guess, lol. Point is, I know a little but really need and want to learn more so I'm really happy to log on this morning and see all of your replies. Very helpful! I really need to get up on my lathe/mill feeds and speed knowledge too and am working on that now. -John

- Joined

- Jun 12, 2014

- Messages

- 4,826

Not a big fan of 1018, in particular for turning. I only use it as cold rolled plate. I find you will get much better finish with CR1144, 4130/4140 series, 8620 and O1 all which are quite common in rod, sold in shorter sections/drops. You need to take a deep enough cut where you are actually getting chips and need way more feed to break the chips. It gets tougher to break the chips with the 4000 and 8000 steel series. I do get good finish with hot rolled but with a larger nose diameter, deeper cut and higher feed rate. If you are making parts in aluminum you must use climb cutting and also some form of air/lube system is needed to clear the chips so they do not regrind. With aluminum, I prefer to work with 7075 if you can find it, it machines more like steel, less gummy. Use rougher for bulk metal removal.

I have attached some drawings for a nice slitting saw that I made years ago and a friend drew up the plans. If I recall I used O1 steel, he made his from 1144, they both turned out very nice. It is a good turning project.

I have attached some drawings for a nice slitting saw that I made years ago and a friend drew up the plans. If I recall I used O1 steel, he made his from 1144, they both turned out very nice. It is a good turning project.