If you want to go where others fear to tread, there are HM projects, and links to complete re-works that will take out the wear ridges, and scrape the ways, and end up with something aligned along it's whole length. Do not go there unless you are completely aware of what it takes. The end result is beautiful, but a hard road to get there.

One can have the bed ways re-ground. This can cost more than you think the kit is worth, but I have heard some places can do it for $400 - $500. Setting up a good bed regrind is not trivial. You have to trust the firm has the skills and experience. You have to keep in mind some other "adjustments" needing shimming or whatever to take care of the position of the carriage relative to the leadscrew, and it's gears, etc. if the regrind lowered the bed beyond the trivial. That you got it as a freebie may affect your decision (or cloud your judgement).

From the Connelly "Machine Tool Reconditioning", available on this site, he counsels "top down" method. I have seen YT videos on how the bed ways scraping was progressively adjusted to get the travel relative to the spindle axis exact while doing the minimum of metal removal work.

There us one (scary) set of videos where first the unworn surfaces, tops of ways, front side and under, etc. were established, then he set up a ghetto arrangement using an old router to re-grind the ways keeping parallel to the original spindle axis. The outcome was a work of art, but I am not sure he would do another like that.

Even with the localized wear, a bit of judicious scraping to in effect make the unworn parts "catch up" can make a superb lathe performer. That is another route I will not go! The lathe works well enough without it.

Plating Experiment

I have been the route discovering how to mask the unworn heights, and locally apply homebrew nickel electroplating to add metal to to low regions, and then scrape back to original.

It worked, but it is my little adventure. I had nothing much to lose, because I acquired the whole lathe, 4-jaw chucks, tooling, bench etc. for less than 150 bucks. Yes, I did it to a "test" section of the ways. Yes, it takes ages to build up enough nickel, and my wear ridge is not as deep as yours. Yes, nickel is much harder to scrape than bed-iron. Some of my plating stuff is in HM posts. I may go there again, but the best discovery is that a 3 minute dunk in nickel-loaded vinegar leaves a part so it will never rust again! I now have other nickel solutions, and I still may go at it again this way. I also might be the only nutter in the entire HM membership who would attempt this.

I have two SB9s, one working, and one in pieces. Playing with restoring one machine, sometimes using the other to do it, is as much fun as machining for any other project. On the way, I may end up with the most measured SB9 anywhere.

Measure it a little

Get a bit of pipe, plug the ends good enough to face and and give centers. Weld in some metal, or JB Weld glue it, whatever. Cut the central region a bit down leaving the dumb-bell ends, and make a test bar. Use a micrometer on them. Use a eBay test bar with indicator to check alignment. Even just turn something and measure to check if you are not making a taper. You may be more than satisfied, and happy to leave the lathe as it is, but you have to be sure of the line between the lathe condition, and your turning and measuring skills.

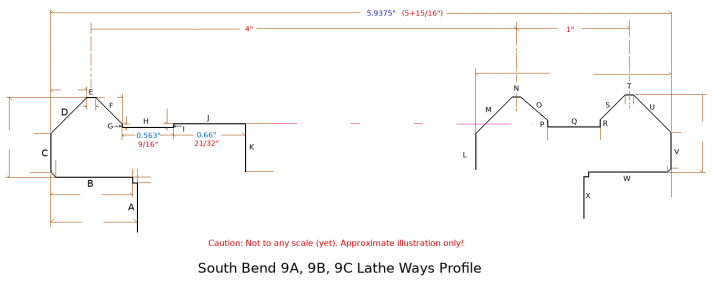

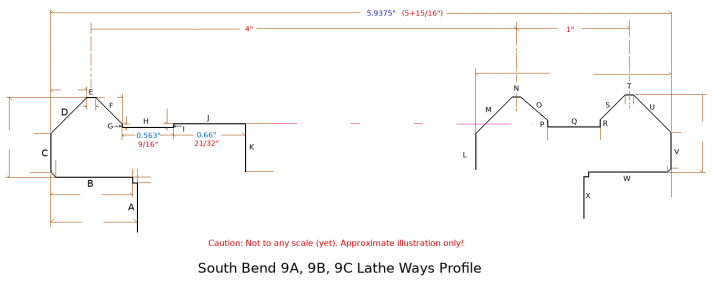

Above is my homebrew nominal profile of the major factory measurements.

Surfaces B, C, E, H, N, T, V, and W have a very good chance of being accurately aligned to the original axis.

Surfaces E, N , T may have got a bit dinged up in places, but usually are still close enough to "unworn" to set a level on.

Establishing something you trust, like standing blocks on H and Q, or using E and N is essential if you want to asses the condition.

Of course, one of the first things you do is put an indicator on the carriage, and test down to H, or against C, to discover just how much the carriage sinks in a worn area. Simply because the carriage ways straddle a wide region, and average out the wear, you could be surprised how little the accuracy is affected by a whole lot of wear.

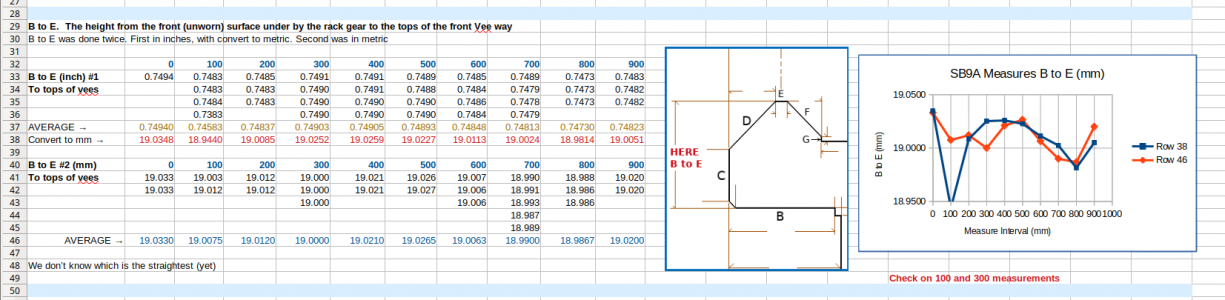

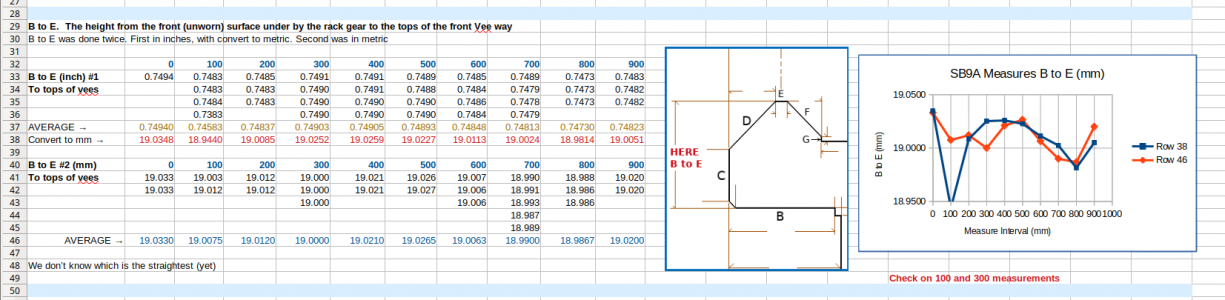

I do have my partly filled out spreadsheet , measuring up the profile in sections, in tables for the length of the bed every 100mm. I will post if you like, but most folk here use inches, and they can probably make a spreadsheet just as well as I can.

As sample fragment looks like this -->

From your real nice pictures, my impression is that the lathe looks nothing like the rusted up hell that many of them end up in. So far, everyone is saying keep it and use it. If not, at the very least,

@Superburban will have it. Clean up, measure up, and you may find that with few minor tweaks and maintenance, you have something nice.

Suggest..

1. Perhaps get the tailstock adjusted true.

2. Maybe pay attention to the chuck jaws (lots of info her on how to do that)

3. Check out the leadscrew nut. Keep, replace or make another.

4. Check for backlash in slide adjusts. This is partly about the ACME thread, and what it runs in, and partly about the shim washer(s). There has to be at least some tiny amount, or you never know if the tool is true in the direction you are going.

5. Of course, check it out for basic catastrophic stuff - like missing gear teeth. Motor must run, connections and switches safe.

6. Get all the gibs adjusted up sweet. Make sure the oilers are accepting oil.

7. Peek up the tapers. They may need a clean-out, and possibly a gentle refresh with a

hand MT2 or MT3 reamer.

On that last point, take care, I have recently discovered that some SB9s were made with MT2 at both ends, and some had MT3 spindle with MT2 tailstock.

Try it! If it still leaves you unhappy, send PM to

@Superburban