- Joined

- Jul 5, 2014

- Messages

- 2,772

OK, sounds weird I know.

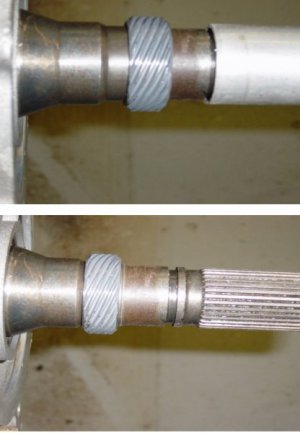

I have a steel speedometer gear I need to secure on a shaft inside an automatic transmission. I can machine it for a light press fit and in the instructions say use a piece of aluminum tubing and a soft hammer totap it on, but in the real world a customer will use steel tubing and their splitting maul to install it.

The problem is that if they hit it too hard they will damage the transmission. The output shaft uses a snap ring inside the transmission case to stop forward movement of the clutch drum and they will break the groove in the case and pretty much scrap the trans.

I've thought about possibly drilling the edge of the steel gear at a 45 degree angle and using set screws to lock it, but they will have to be pretty small screws. I'm not sure if a locking compound will work considering the inside temp of the trans could reach 200 degrees.

Any thoughts or ideas you have will be appreciated.

I have a steel speedometer gear I need to secure on a shaft inside an automatic transmission. I can machine it for a light press fit and in the instructions say use a piece of aluminum tubing and a soft hammer totap it on, but in the real world a customer will use steel tubing and their splitting maul to install it.

The problem is that if they hit it too hard they will damage the transmission. The output shaft uses a snap ring inside the transmission case to stop forward movement of the clutch drum and they will break the groove in the case and pretty much scrap the trans.

I've thought about possibly drilling the edge of the steel gear at a 45 degree angle and using set screws to lock it, but they will have to be pretty small screws. I'm not sure if a locking compound will work considering the inside temp of the trans could reach 200 degrees.

Any thoughts or ideas you have will be appreciated.

Attachments

Last edited: