-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Seneca Falls Star #30 lathe Resto-Mod

- Thread starter derf

- Start date

- Joined

- Oct 3, 2015

- Messages

- 983

Now that most of the major dilemmas were conquered, it was time to pick the dried rotten meat from this old dinosaur's bones. The bed and legs still had remains of japanning and gilsonite in places that were hard to get to. The easier stripping was done by previous owners and then covered by the nauseating pea green paint. Starting out with oven cleaner to knock the lion share off, then down to primitive weapons like wire brushes and wheels and in some spots, picks and shovels. A good blast with a pressure washer got it to 90% clean.

I couldn't get anything this big in my blast cabinet, the rest was all wiped down by hand. I must say, the fillers they used 100 yrs ago were still hard as concrete, and if it weren't for the fact that in some places it was applied sloppy and unsightly, I would have left in on.

A little elbow grease and it came out good. The inside not so much. I decided to paint the inside of the bed with red rustoleum and even after 3 coats the gilsonite still bled through a little.

I did get very lucky when it came to removing the legs. It just so happens that my rolling work bench would slide right under and between the legs of the lathe, with 1/2" to spare.

Once in position, I slid a couple of wood wedges between the bed and the bench to take the weight off the legs so I could unbolt them. When we got down to just the bed, it was easy to handle on the bench top. Oh, did I mention that every fastener on this thing has a square head? Most were accessible with a open end wrench, but there were a few that needed a socket....a size that I didn't have. So I had to get creative and modify a chinese socket to remove those, and of course they all got replaced with modern stuff.

Since this was down as basic as it would go, we had a serious discussion about a chip pan.

It was not going to be simple with the full length cast legs because of the flare and the taper. I wanted a pan that didn't have any open spots and looked like it belonged there.

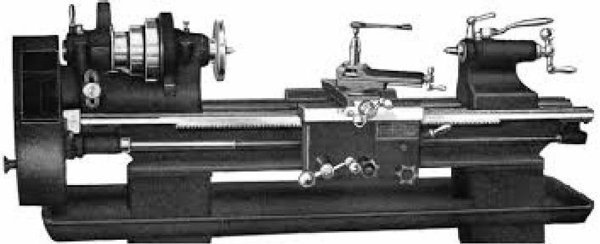

There were factory models that had pans:

As you can see, the pan was sandwiched between the sub bases and the legs, like many other lathes of the era. I really did not want to get into a total new set of legs and risers and etc...so I came up with a simpler plan.

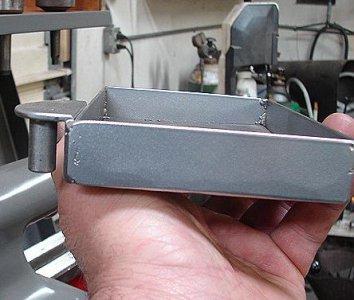

This consisted of fabricating some boxes that resembled a top hat so to speak, that is square rather than cylindrical. The boxes are dropped over the legs, and extend down 5" with a flange on the bottom.

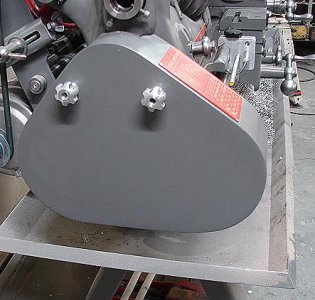

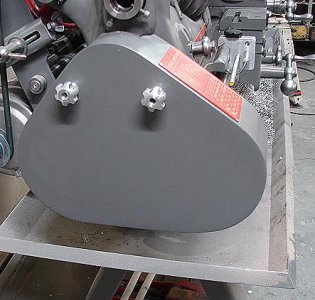

The chip pan has 2 square holes cut in and then dropped over the boxes as shown in this inverted pic.

Upon final assembly, the pan was secured to the boxes with button head machine screws.

I couldn't get anything this big in my blast cabinet, the rest was all wiped down by hand. I must say, the fillers they used 100 yrs ago were still hard as concrete, and if it weren't for the fact that in some places it was applied sloppy and unsightly, I would have left in on.

A little elbow grease and it came out good. The inside not so much. I decided to paint the inside of the bed with red rustoleum and even after 3 coats the gilsonite still bled through a little.

I did get very lucky when it came to removing the legs. It just so happens that my rolling work bench would slide right under and between the legs of the lathe, with 1/2" to spare.

Once in position, I slid a couple of wood wedges between the bed and the bench to take the weight off the legs so I could unbolt them. When we got down to just the bed, it was easy to handle on the bench top. Oh, did I mention that every fastener on this thing has a square head? Most were accessible with a open end wrench, but there were a few that needed a socket....a size that I didn't have. So I had to get creative and modify a chinese socket to remove those, and of course they all got replaced with modern stuff.

Since this was down as basic as it would go, we had a serious discussion about a chip pan.

It was not going to be simple with the full length cast legs because of the flare and the taper. I wanted a pan that didn't have any open spots and looked like it belonged there.

There were factory models that had pans:

As you can see, the pan was sandwiched between the sub bases and the legs, like many other lathes of the era. I really did not want to get into a total new set of legs and risers and etc...so I came up with a simpler plan.

This consisted of fabricating some boxes that resembled a top hat so to speak, that is square rather than cylindrical. The boxes are dropped over the legs, and extend down 5" with a flange on the bottom.

The chip pan has 2 square holes cut in and then dropped over the boxes as shown in this inverted pic.

Upon final assembly, the pan was secured to the boxes with button head machine screws.

- Joined

- Oct 3, 2015

- Messages

- 983

As you can see, we're to the point of puttin' some fresh lipstick on this pig, and most of the sub assemblies were painted as there were rebuilt and re-assembled to to keeps all the parts together. We settled on Majic Massey-Ferguson gray tractor enamel, using the gloss hardner and japan drier. It is slightly darker than South Bend gray, but still that "classic machine gray" hue.

When we got to point of having all the components on place, It was time to fab up a back splash, now that it has a fancy chip pan to attach to.

The back splash covers the front to form a 12" shelf. The shelf is made from 3/4" plywood salvaged from a cabinet door.

This machine did not come with a gear box cover, nor a provision for mounting one, and of course it didn't come with all the gears either, so I had to make both. I made the cover slightly different that the factory version, so it had room for an outboard spider. The spider is actually an extended spindle nut I made about 3/4" longer than oem, and d&t for 1/4-20

screws.

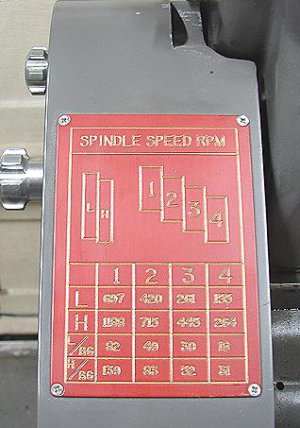

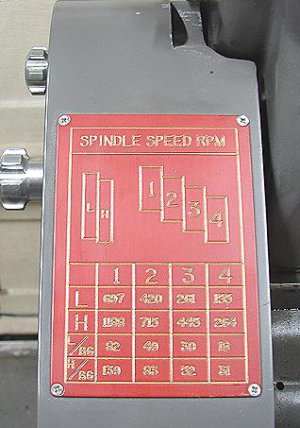

Attached to the guard is a spindle speed chart I engraved on my cnc mill.

This machine came with 4 gears out of the original 11 that they came with. I knew it was a waste of time looking for missing gears and I would somehow have to make some. It was just a matter of how to attack this situation. The gears were 14 DP, and reasonable costing gear cutters were scarce. After a lot of research, I decided to make the cutter myself. I got the best information about easy gear cutting from this website: http://www.david.rysdam.org/

He tells how to make a single cutter to cut a whole range of teeth. I used a simple spindex on the gears that was divisible, and made indexing plates on my cnc mill for the ones that weren't.

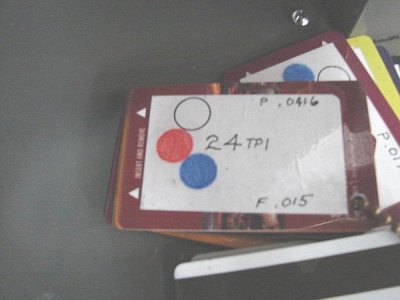

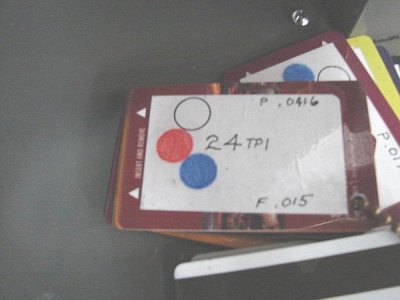

For ease of machining, I used 6061 aluminum. For ease of set-up, I color coded the gears and made up index cards.

When we got to point of having all the components on place, It was time to fab up a back splash, now that it has a fancy chip pan to attach to.

The back splash covers the front to form a 12" shelf. The shelf is made from 3/4" plywood salvaged from a cabinet door.

This machine did not come with a gear box cover, nor a provision for mounting one, and of course it didn't come with all the gears either, so I had to make both. I made the cover slightly different that the factory version, so it had room for an outboard spider. The spider is actually an extended spindle nut I made about 3/4" longer than oem, and d&t for 1/4-20

screws.

Attached to the guard is a spindle speed chart I engraved on my cnc mill.

This machine came with 4 gears out of the original 11 that they came with. I knew it was a waste of time looking for missing gears and I would somehow have to make some. It was just a matter of how to attack this situation. The gears were 14 DP, and reasonable costing gear cutters were scarce. After a lot of research, I decided to make the cutter myself. I got the best information about easy gear cutting from this website: http://www.david.rysdam.org/

He tells how to make a single cutter to cut a whole range of teeth. I used a simple spindex on the gears that was divisible, and made indexing plates on my cnc mill for the ones that weren't.

For ease of machining, I used 6061 aluminum. For ease of set-up, I color coded the gears and made up index cards.

- Joined

- Oct 3, 2015

- Messages

- 983

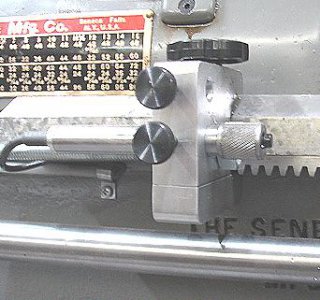

Even though the color coded gears and the cheat sheets make it easier to set up for threading, I find it slightly annoying to have to change gears around for general turning. I have 3 lathes with quick change gear boxes, so I might be a bit biased. To get around that monkey motion, the best idea that I've seen in many moons was to power the lead screw with an electric motor. I found enough info here and other places on the net to proceed.

I did give this some fore thought however when I had the machine down to basics. While the lead screw was out of the machine, I drilled and reamed a 1/2" hole in the tail end of the screw, and added a 1/8" crosscut for a way to drive it. The screw was retained by two flat bottom plugs for end play. I removed the plugs and made a threaded bushing that would retain the end play and allow a 1/2" drive rod to protrude out to a motor drive. The 1/2" shaft fits into the screw about 1", and is driven with a 1/8" pin in the crosscut. The crosscut is about .135" deep, so the drive pin is slightly below flush and the bushing controls the end play of the screw with a jamb nut. On the other side of the jamb nut is more threads and a nut to locate a motor mount.

The mount was made to be dis-engaged when using the spindle powered drive train, so the motor and gear simply swing away from the screw gear.

Basically I used a wiper motor like everyone else had success with, that was rated at 50 rpm on the hi side and 35 rpm on the low. I originally made the gearing 1:1, and it proved to be too slow, so I went with 2:1, with a little concern about torque loss. I actually checked the rpm with a tach and it was 42 rpm on the hi side and 34 on the low. At first I wired it for 2 speed operation and it made absolutely no sense to have 2 speeds when you have a pot to adjust current. So I eliminated a switch and just wired up the hi speed side. For the speed control we used pwm and crammed that and the power supply into a control box that I had left over from an old Bridgeport. I had to made a new cover to accommodate the switches tastefully.

The power supply is wired through the drum switch so the screw has no power if the spindle is not running. As a safety feature, so the electric powered screw is not conflicting with the spindle powering the screw at the same time, a push button momentary switch was installed below the banjo. The banjo must be swung down, dis-engaging the gear train, then activating the switch.

By doing this, the only way to get power to the screw is obvious.

In the same circuit, there is also a limit switch. This switch can be set to stop the screw, thus stopping the carriage at any point. It can also be operated by hand, which is handy when the feed clutch is a star knob. I find feed levers more natural and responsive than a knob. So you can depress the button at the end of a cut, and then release the feed clutch knob without the worries of bad timing.

As I mentioned before, I had some reservations about loss of torque by going 2:1 on the driver motor, so I figured the best way to find out is to turn something. I found an old stainless rifle barrel and chucked it up. I set the spindle speed in 3rd gear (715 rpm) and was using a ccmt insert, took a .015" doc and flipped the switch. I turned it up to full throttle and watched nice little chips fly off with no effort. Then I decided to go from feed, to using the half nut, which is the feed rate x 2.77.

I noticed a small slow down, (at least it sounded that way) but still with the throttle up, it was throwing chips faster than I could get away from them! From my best guess, it was about .025" per rev. Needless to say...I was impressed. Now that I know it works well, I dressed it up with a gear cover.

I did give this some fore thought however when I had the machine down to basics. While the lead screw was out of the machine, I drilled and reamed a 1/2" hole in the tail end of the screw, and added a 1/8" crosscut for a way to drive it. The screw was retained by two flat bottom plugs for end play. I removed the plugs and made a threaded bushing that would retain the end play and allow a 1/2" drive rod to protrude out to a motor drive. The 1/2" shaft fits into the screw about 1", and is driven with a 1/8" pin in the crosscut. The crosscut is about .135" deep, so the drive pin is slightly below flush and the bushing controls the end play of the screw with a jamb nut. On the other side of the jamb nut is more threads and a nut to locate a motor mount.

The mount was made to be dis-engaged when using the spindle powered drive train, so the motor and gear simply swing away from the screw gear.

Basically I used a wiper motor like everyone else had success with, that was rated at 50 rpm on the hi side and 35 rpm on the low. I originally made the gearing 1:1, and it proved to be too slow, so I went with 2:1, with a little concern about torque loss. I actually checked the rpm with a tach and it was 42 rpm on the hi side and 34 on the low. At first I wired it for 2 speed operation and it made absolutely no sense to have 2 speeds when you have a pot to adjust current. So I eliminated a switch and just wired up the hi speed side. For the speed control we used pwm and crammed that and the power supply into a control box that I had left over from an old Bridgeport. I had to made a new cover to accommodate the switches tastefully.

The power supply is wired through the drum switch so the screw has no power if the spindle is not running. As a safety feature, so the electric powered screw is not conflicting with the spindle powering the screw at the same time, a push button momentary switch was installed below the banjo. The banjo must be swung down, dis-engaging the gear train, then activating the switch.

By doing this, the only way to get power to the screw is obvious.

In the same circuit, there is also a limit switch. This switch can be set to stop the screw, thus stopping the carriage at any point. It can also be operated by hand, which is handy when the feed clutch is a star knob. I find feed levers more natural and responsive than a knob. So you can depress the button at the end of a cut, and then release the feed clutch knob without the worries of bad timing.

As I mentioned before, I had some reservations about loss of torque by going 2:1 on the driver motor, so I figured the best way to find out is to turn something. I found an old stainless rifle barrel and chucked it up. I set the spindle speed in 3rd gear (715 rpm) and was using a ccmt insert, took a .015" doc and flipped the switch. I turned it up to full throttle and watched nice little chips fly off with no effort. Then I decided to go from feed, to using the half nut, which is the feed rate x 2.77.

I noticed a small slow down, (at least it sounded that way) but still with the throttle up, it was throwing chips faster than I could get away from them! From my best guess, it was about .025" per rev. Needless to say...I was impressed. Now that I know it works well, I dressed it up with a gear cover.

- Joined

- Oct 3, 2015

- Messages

- 983

- Joined

- Oct 3, 2015

- Messages

- 983

I discovered that I had a coupla steel drawers that were covered in dust under one of my work benches. These came off a cheap roller tool cart, but they did have have nice slides.

Although they don't match, they will do the job, so I mounted them under the chip tray.

I had mentioned before, that the chuck would be replaced. I wasn't in no hurry, but a chuck solution was needed, whether it was now, or down the road. The thread on the spindle is 1-9/16" x10 tpi....not common by any means. I tore the original 3 jaw down just to find the normal wear for a 100 yr. old chuck...kinda sloppy. So I cleaned it up and took a dusting off cut to reveal some fresh metal.

I had never seen a chuck that had square head adjusters, but the bad thing is that they protrude outside the periphery of the chuck body about 3/16"....not something I feel safe about.

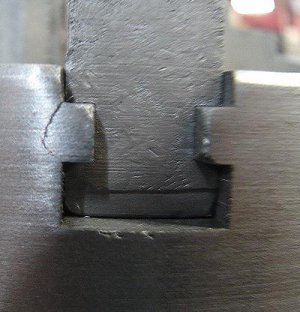

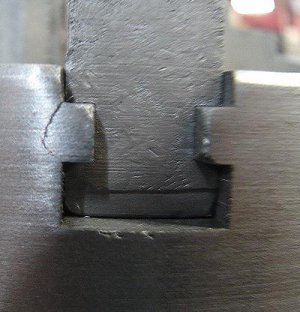

I'm actually glad that I made a clean up cut on the outside surfaces, because under all that patina, here's what I found:

Every one of the T slots had at least one crack, some had 2. I guess we're chuck shopping now.

Although they don't match, they will do the job, so I mounted them under the chip tray.

I had mentioned before, that the chuck would be replaced. I wasn't in no hurry, but a chuck solution was needed, whether it was now, or down the road. The thread on the spindle is 1-9/16" x10 tpi....not common by any means. I tore the original 3 jaw down just to find the normal wear for a 100 yr. old chuck...kinda sloppy. So I cleaned it up and took a dusting off cut to reveal some fresh metal.

I had never seen a chuck that had square head adjusters, but the bad thing is that they protrude outside the periphery of the chuck body about 3/16"....not something I feel safe about.

I'm actually glad that I made a clean up cut on the outside surfaces, because under all that patina, here's what I found:

Every one of the T slots had at least one crack, some had 2. I guess we're chuck shopping now.