- Joined

- Feb 8, 2014

- Messages

- 11,144

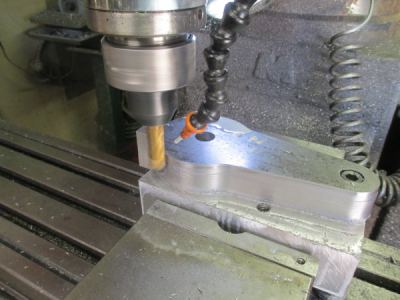

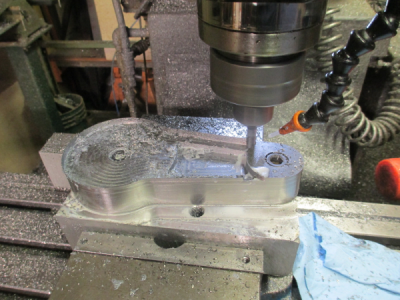

A customer asked me to build a special high speed punch press for punching some plastic parts from a strip. I can't go into any product detail, but I can give the general specifications for the machine.

Target speed: 600 hits/min, more realistically 300 or so I'm guessing.

On-the-fly infinitely variable feed length from 1 inch to 6 inches

Easily adjustable for different punch patterns.....More on this later.

Because it's punching plastic, a push-pull feed system

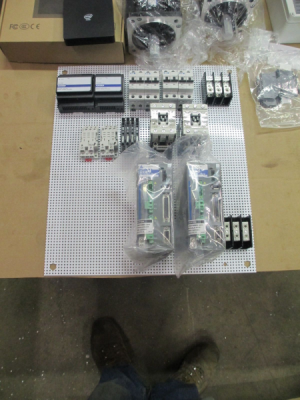

1.8KW servo drives on both the feed and crankshaft drive.

Touch screen operator interface.

2 axis Galil motion controller

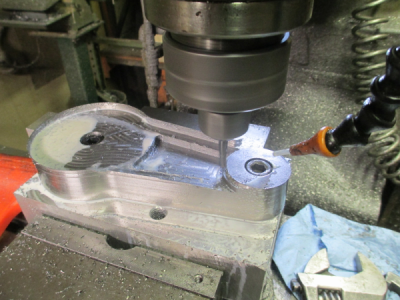

Just a teaser picture...I'll post more later

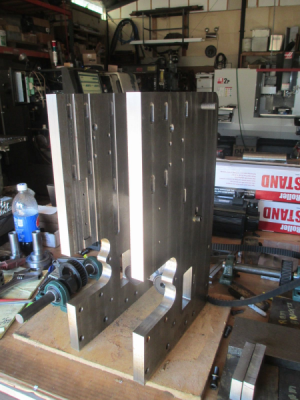

One of the side frames 12x20x1 A36 steel

Target speed: 600 hits/min, more realistically 300 or so I'm guessing.

On-the-fly infinitely variable feed length from 1 inch to 6 inches

Easily adjustable for different punch patterns.....More on this later.

Because it's punching plastic, a push-pull feed system

1.8KW servo drives on both the feed and crankshaft drive.

Touch screen operator interface.

2 axis Galil motion controller

Just a teaser picture...I'll post more later

One of the side frames 12x20x1 A36 steel