- Joined

- Mar 21, 2013

- Messages

- 4,063

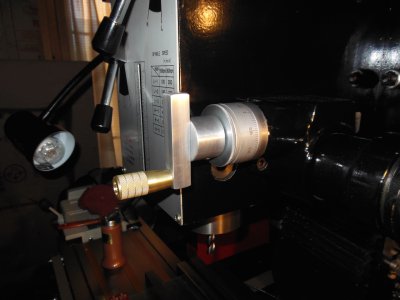

Thank you so much for relating your setup experiences with this product.

Our members want to see what's involved.

Hello Nels, didn't think you visited down here.

And given the number of views this thread has had, I tend to agree with your statement about wanting to see this thing. I was starting to worry that I might be taking up too much space with this thread and thought about stopping. It's not too big?

...

...