-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Setup and Continuing Saga of the Charter Oak 12Z

- Thread starter wrmiller

- Start date

Hi guys: First post and happy to find this forum. It will take a while to get up to speed.

Just a little fun but this is how you use the red steel thing I sent.

https://www.youtube.com/watch?v=WacnLxxvohE

Hope it all works well for you.

Dave

Cool video...

Wish mine was that easy to reach... I have a PM935... I have to reach 'up there' to those fittings...

Welcome to HM forum!

Look around... then pull up a chair, open a container of your favourite beverage, put your feet up, and tell us about your interests with metalworking.

- Joined

- Mar 21, 2013

- Messages

- 4,063

Wow...

First I unbolted the motor from the top plate and attempted to lift it. Nothing doing. OK. Then I thought it had to come off with the top plate, so I removed the four bolts in the front half of the top plate. Plate was 'slightly' loose at the front but the back wasn't moving. Checked the new top plate and there are holes back there for two more bolts. But they are under the motor flange. Seriously? So I start prying the motor up as evenly as I can from opposing sides at the same time. I managed to get it up about 1/4" or so and looked under it and yup, there are two more bolts in the top plate. I then look at the motor shaft and expect to see the drive gear coming up with the motor. Nope. I see a shaft and key all covered in corrosion being pulled out of a shaft or something.

It takes me the better part of two hours to get the motor off (I'm trying to pry evenly on the motor, but it's taking both hands so I started wondering if I could catch the motor when it finally comes loose. Good news...I didn't drop it) and the top plate. David says that after the top plate comes off, you need to take out the shifter forks before the gears. Well, when I finally got the top plate loose and lifted it off all of the gears/shafts came with it except for one. Oops...

This is the one shaft that didn't come out, but it was just sitting cockeyed/loose in the bottom of the head. It tried to come out with everyone else.

And here's what was left in the head. There is a little bit of powder (iron probably) in the bottom of the head. It has some gold flecks in it too.

There was this blue sealant stuff everywhere, and it was still soft like it just came out of the tube. But after pulling the front plate off I could see where the oil was leaking down the front and onto my vise. Scraped all that crap off. Good riddance.

The belt drive kit comes with a new front cover that doesn't have holes in it for the shifter levers. Maybe I can get someone to put El Hefe on it. :roflmao:

I'm going to sop up as much of that residual oil as I can, and figure out how to get the shift levers out. Then tomorrow I can deal with mounting the motor and drive pulley to the new plate and getting the pulleys aligned. Should be a piece of cake after that. (where have I heard THAT before?)

First I unbolted the motor from the top plate and attempted to lift it. Nothing doing. OK. Then I thought it had to come off with the top plate, so I removed the four bolts in the front half of the top plate. Plate was 'slightly' loose at the front but the back wasn't moving. Checked the new top plate and there are holes back there for two more bolts. But they are under the motor flange. Seriously? So I start prying the motor up as evenly as I can from opposing sides at the same time. I managed to get it up about 1/4" or so and looked under it and yup, there are two more bolts in the top plate. I then look at the motor shaft and expect to see the drive gear coming up with the motor. Nope. I see a shaft and key all covered in corrosion being pulled out of a shaft or something.

It takes me the better part of two hours to get the motor off (I'm trying to pry evenly on the motor, but it's taking both hands so I started wondering if I could catch the motor when it finally comes loose. Good news...I didn't drop it) and the top plate. David says that after the top plate comes off, you need to take out the shifter forks before the gears. Well, when I finally got the top plate loose and lifted it off all of the gears/shafts came with it except for one. Oops...

This is the one shaft that didn't come out, but it was just sitting cockeyed/loose in the bottom of the head. It tried to come out with everyone else.

And here's what was left in the head. There is a little bit of powder (iron probably) in the bottom of the head. It has some gold flecks in it too.

There was this blue sealant stuff everywhere, and it was still soft like it just came out of the tube. But after pulling the front plate off I could see where the oil was leaking down the front and onto my vise. Scraped all that crap off. Good riddance.

The belt drive kit comes with a new front cover that doesn't have holes in it for the shifter levers. Maybe I can get someone to put El Hefe on it. :roflmao:

I'm going to sop up as much of that residual oil as I can, and figure out how to get the shift levers out. Then tomorrow I can deal with mounting the motor and drive pulley to the new plate and getting the pulleys aligned. Should be a piece of cake after that. (where have I heard THAT before?)

- Joined

- Mar 21, 2013

- Messages

- 4,063

Now we're cooking with gas...  )

)

The tapered bushing for the motor pulley has it's draw-down bolts facing the motor so getting the pulleys aligned was a lot of trial and error but I think I have it pretty close.

So tomorrow I will be putting the top plate and motor back on the head. Now David warned me that the spindle may not be perfectly perpendicular to the top plate mounting surface which can cause noise amongst other things. Shims? Guess I'll find out tomorrow. My left bicep is starting to ache from picking up this motor about 50 times (at least) so I'm calling it a night. This thing is fairly heavy for only a 3hp motor.

That or I'm just getting too old... :roflmao:

EDIT: Oh, and I was mistaken about the powder in the bottom of the head. There wasn't any. Just some of that blue stuff that looks black under oil, and some bare spots that didn't get painted. Head was very clean once I got the remaining oil out.

The tapered bushing for the motor pulley has it's draw-down bolts facing the motor so getting the pulleys aligned was a lot of trial and error but I think I have it pretty close.

So tomorrow I will be putting the top plate and motor back on the head. Now David warned me that the spindle may not be perfectly perpendicular to the top plate mounting surface which can cause noise amongst other things. Shims? Guess I'll find out tomorrow. My left bicep is starting to ache from picking up this motor about 50 times (at least) so I'm calling it a night. This thing is fairly heavy for only a 3hp motor.

That or I'm just getting too old... :roflmao:

EDIT: Oh, and I was mistaken about the powder in the bottom of the head. There wasn't any. Just some of that blue stuff that looks black under oil, and some bare spots that didn't get painted. Head was very clean once I got the remaining oil out.

- Joined

- Jul 23, 2014

- Messages

- 347

Bill, your mention of spindle grease jolted a memory. Are you going to Kluber grease the spindle bearings?

- Joined

- Mar 21, 2013

- Messages

- 4,063

Bill, your mention of spindle grease jolted a memory. Are you going to Kluber grease the spindle bearings?

Hi Jon, haven't heard from you in a while. How have you been?

Honestly, I hadn't thought about it. CO upgraded the bearings when the 3 hp motor was put on. Paul told me they are good to 7k for short bursts but should run at 5k all day. I 'assumed' he had his people use an appropriate grease, but I'll send him a line and ask what he used. Thanks.

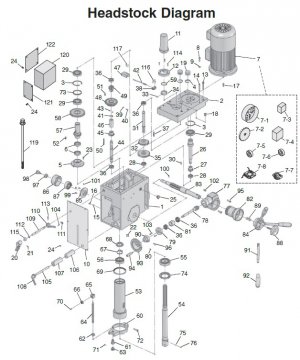

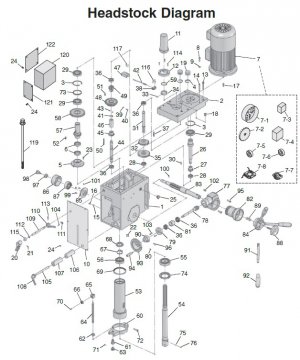

It sure would be nice if I had a exploded view/parts diagram for this thing.

- Joined

- Mar 21, 2013

- Messages

- 4,063

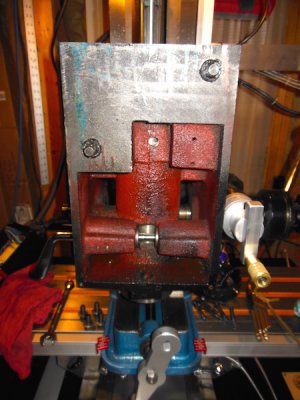

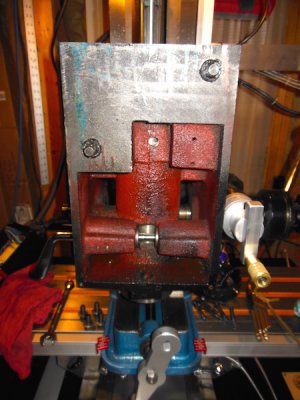

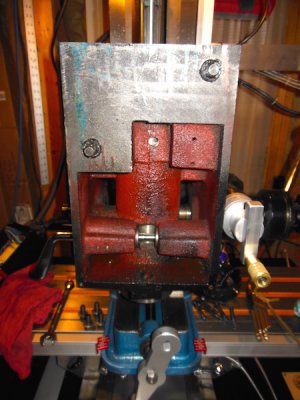

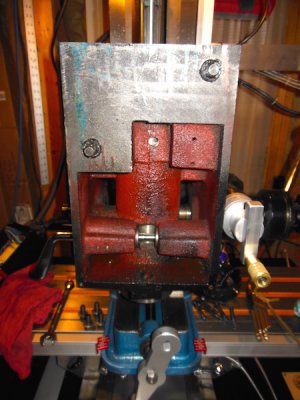

Well, tried to put the motor/top plate assy. onto the head and ran into a slight problem.

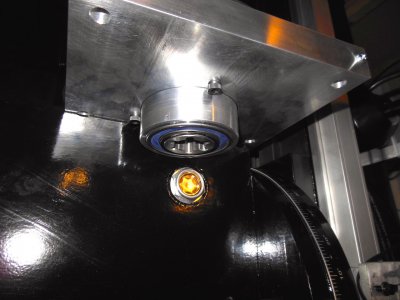

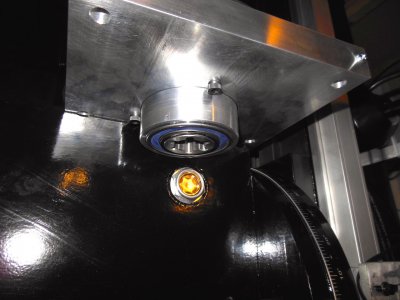

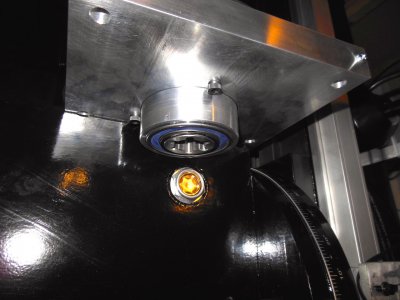

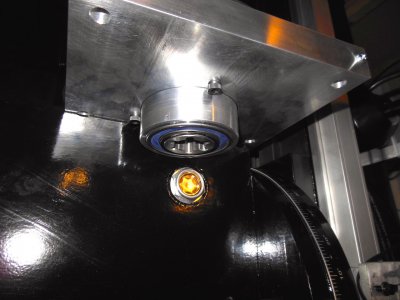

The bearing/spline housing on the bottom front of the top plate sits too far down into the head.

And the bearing runs into the bearing(?) collar around the spindle.

There is about 1/2" or so of 'interference fit' such that the top plate won't come all the way down to it's mating surface on the head. anic:

anic:

Sent David a email, waiting to hear back. Nothing is ever easy...

The bearing/spline housing on the bottom front of the top plate sits too far down into the head.

And the bearing runs into the bearing(?) collar around the spindle.

There is about 1/2" or so of 'interference fit' such that the top plate won't come all the way down to it's mating surface on the head.

Sent David a email, waiting to hear back. Nothing is ever easy...

- Joined

- Dec 18, 2013

- Messages

- 2,012

Seems like you would need to remove that factory piece in photo 2 bill, I'm assuming that's with the spindle all the way down, there's not much of the splined spindle for the belt drive to grab onto without removing that factory piece.

- Joined

- Dec 18, 2013

- Messages

- 2,012

It sure would be nice if I had a exploded view/parts diagram for this thing.

Abracadabra here's a link to the PDF, its clear and you can zoom way in on the exploded view http://cdn0.grizzly.com/manuals/g0762_m.pdf

- Joined

- Mar 21, 2013

- Messages

- 4,063

Yes, the second pic is with the spindle fully extended.

And a BIG thankyou for the pdf. I looked at that mill but wasn't sure if it would be the same. Going to go out and take new look at that top piece on the spindle.

And a BIG thankyou for the pdf. I looked at that mill but wasn't sure if it would be the same. Going to go out and take new look at that top piece on the spindle.