- Joined

- Jan 29, 2014

- Messages

- 64

Earlier this year I bought me a shaper. At first I did know what brand it was but after some intensive search on the net I discovered that is was a Shape-rite 8”.

As you can see there are some parts missing, the motor for instance and a plate behind the arm, and the drive pulleys

On the net I found an engine ¾ hors power 380 volt 3 phase for 20 Eur ( 25$) The same guy had a step pulley which I could use and has about the same measurements as on the pictures I found on the net. The hole however is to large for the axle so I need to make a bushing for it.

Today I've taken everything apart except a few axles which will be removed at a later day.

Buy cleaning some of the ways I discovered the following markings “ Made in U.S.A 1089 B”

This is my new project for the next few weeks.

As you can see there are some parts missing, the motor for instance and a plate behind the arm, and the drive pulleys

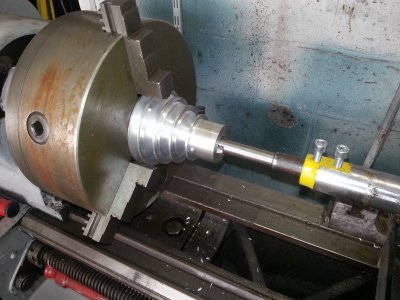

On the net I found an engine ¾ hors power 380 volt 3 phase for 20 Eur ( 25$) The same guy had a step pulley which I could use and has about the same measurements as on the pictures I found on the net. The hole however is to large for the axle so I need to make a bushing for it.

Today I've taken everything apart except a few axles which will be removed at a later day.

Buy cleaning some of the ways I discovered the following markings “ Made in U.S.A 1089 B”

This is my new project for the next few weeks.