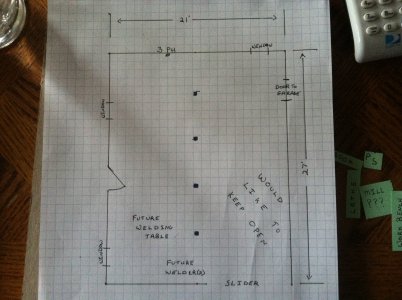

I'm thinking of rearranging the place yet again. Right now I have (mostly)everything to build a 12 foot workbench. But I'm thinking that will just end up a HUGE catch all and no work space. :whistle: Also if I do that all of the equipment/machines will be out in the middle. So I was thinking of shorting the bench and putting the lathe against a wall and leaving space in the corner for a future mill. To do this I will seriously shorten my bench.

What is your thoughts on this? Also do you prefer your machines up against a wall or out in the open??

Thanks,

Chris

What is your thoughts on this? Also do you prefer your machines up against a wall or out in the open??

Thanks,

Chris