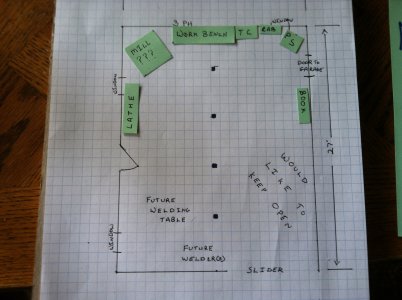

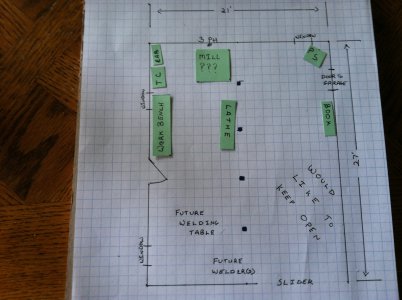

I thought about that. But right where the lathe is sitting, is my 3 phase plugs. I could put a longer cord on it though :thinking: As for the welding, that's why I would like to put the welder(s) right next to the door. Just string out side and go. Oh and I was planning on putting the bench grinders in the welding "area" to try and keep the mess localized I guess lol.

That apron idea is a good one!! I will have to check into that.

Thanks,

Chris

- - - Updated - - -

Another thought. Do you think I made my "mill" a correct size? I don't have one yet, but would still like to plan for it. I will swap stuff around tonight and post another picture.

That apron idea is a good one!! I will have to check into that.

Thanks,

Chris

- - - Updated - - -

Another thought. Do you think I made my "mill" a correct size? I don't have one yet, but would still like to plan for it. I will swap stuff around tonight and post another picture.