- Joined

- Nov 5, 2019

- Messages

- 218

I bought one of those cheap china boring heads for my ball turner and that screw drilled and tapped easily. I use that end of the screw for feeding all the time.

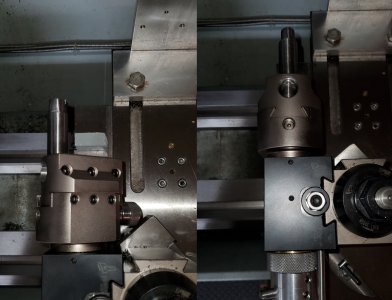

Thanks, Mark.If I recall I drilled and tapped the other end through the center of the hex machined into the end of the knob to hold it on. The OD is such that it fits into the boring head, I had to shorten it so it would not hit the tool post slide. Doing it from the other side is possible but nothing to prevent it from unscrewing/loosening, Probably do the set screw with Loctite.. Black dot is just for rough indexing. I used a Shar's boring head, and a Dorian 5C holder which presented a bit more of a challenge vs a straight boring bar holder. The head has a locking set screw to prevent it from loosening, the shaft has a thrust washer which you can set the tension, and stops that can be used to set the swing. It works well, but need a sharp insert with the largest nose radius for the size insert. I may play around with other types of inserts in the future, not sure how you can cut a complete ball like on my QCTP with the round type.

View attachment 368949

View attachment 368950

View attachment 368951View attachment 368952

Very nice. What did you not like about the round inserts? Mark (mksj) seems to agree with you - he, too, was dissatisfied with round inserts and prefers a CCGT setup (see his post #'s 13 and 22 above). I've never used a ball turner, so I'm curious about the pro's and con's of various assemblies.this is the setup I use for adjusting the head from the other end. The SHCS is held in place with a little Loctite and the Allen key tool is magnetized so it stays in place when swinging the head back and forth. I tried the round cutter shown but it didn't work at all for me. I ended up making a tool holder for a nice small DCMT insert. I can get almost a full ball with that setup.

I got an answer from Ade. He did, in fact, use a Chinese boring head in his build and indicated he had no issues with drilling into the screw. I think we're dealing with a case of apples-and-oranges here. I don't see any likelihood that I'll be able to replicate his approach with the Criterion. I'll study this some more and see if I can come up with a solution.

Thanks to all who responded. We'll see what happens.

Regards,

Terry

Been there, done that! (Kinda.) I turned the black Delrin knob that's on the pictures in my original post. I used an el-cheapo Chinese boring bar from a set that I had laying around - mainly because it's the only thing I had with a 1/2" round shaft. Basically, did that for practice (turned out fine, but not great). After playing with it for awhile, I plan on making a nice aluminum or brass knob.Turning a ball for your new ball turner handle is the mandatory first project by the way!