- Joined

- Dec 12, 2014

- Messages

- 261

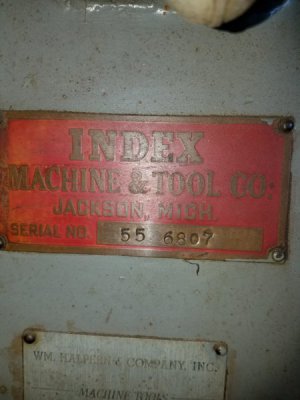

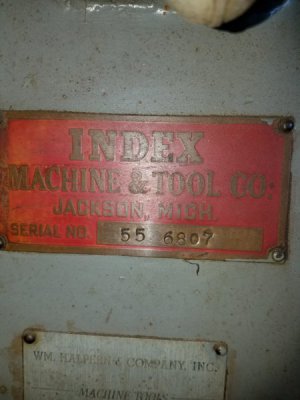

Just got home after having looked at a Index Super 55 vertical mill.

There is not much information that I've found on the internet.

The good: It's cheap. The ways still have alot of the original scraping visible. There is a section near the top of the column that has rust, but a good cleaning may take care of that. I saw it run and no grinding noises, etc. were present. It does actually come with a set of collets.(More on that in just a bit.) It's 3 phase, I've learned after restoring my Sheldon lathe that I actually like 3 phase because the power is oh so smooth.(Love my Sheldon lathe!!) I have no concerns about installing a VFD. I snugged up the gibs on the table and things seemed tight. No loosey-goosey movement.

The bad: It's a B&S taper, but it does come with a set of B&S collets. The X-axis power feed mechanism might be broke or it's missing something. The cover is broke, I know that. The power feed motor and gear train/speed adjustment works fine, it's the long shaft at the table which has me stumped. That bar/keyed shaft will engage and it does rotate when I engage the powerfeed, however I'm thinking a part is missing or something because it's just flopping in the breeze. I'm wondering, how does it stay in-line as it travels with the table lead screw?

The fine feed on the quill is broken, the handle spins completely free with no movement in the quill. Any ideas into how much would be involved to fix this? Is there a common thing that broke on these?

The drawbar spun freely and I could move it upwards about a half inch, but I couldn't pull it out. I put my finger inside the quill and I could wiggle the drawbar and push it upwards, but it wouldn't pull out by hand. It should just be a bar with a thread on the end, right? Is this held in place with some collar/retainer?

I did a little homework before I went to look at the machine. As luck would have it, this was the one machine that Wells-Index did not have information about in their database. The girl on the phone did tell me that she has info on the model before and after, but not this one. I also got a quote for an R8 spindle regrind. It's like $500 which includes shipping.

Is it too far gone? There's that part in my head that says, "DO IT". But, I'm looking for a TOUGH machine away from my days of running the little Atlas horizontal mill.

I'm including pics and a quick video. Ignore the statement I make in the video, about not knowing what the "star" knob is used for. I have read that it allows you to adjust a stop position to prevent accidents with the powerfeed.

Table feed

That bottom shaft is essentially flopping around. It has a worm gear at the power feed engaging handle and it does spin when the powerfeed motor is running.

I could turn the quill power feed pulleys by hand, but no movement on the quill. The fine feed handle on the front spins freely. Probably something broke inside.

There is not much information that I've found on the internet.

The good: It's cheap. The ways still have alot of the original scraping visible. There is a section near the top of the column that has rust, but a good cleaning may take care of that. I saw it run and no grinding noises, etc. were present. It does actually come with a set of collets.(More on that in just a bit.) It's 3 phase, I've learned after restoring my Sheldon lathe that I actually like 3 phase because the power is oh so smooth.(Love my Sheldon lathe!!) I have no concerns about installing a VFD. I snugged up the gibs on the table and things seemed tight. No loosey-goosey movement.

The bad: It's a B&S taper, but it does come with a set of B&S collets. The X-axis power feed mechanism might be broke or it's missing something. The cover is broke, I know that. The power feed motor and gear train/speed adjustment works fine, it's the long shaft at the table which has me stumped. That bar/keyed shaft will engage and it does rotate when I engage the powerfeed, however I'm thinking a part is missing or something because it's just flopping in the breeze. I'm wondering, how does it stay in-line as it travels with the table lead screw?

The fine feed on the quill is broken, the handle spins completely free with no movement in the quill. Any ideas into how much would be involved to fix this? Is there a common thing that broke on these?

The drawbar spun freely and I could move it upwards about a half inch, but I couldn't pull it out. I put my finger inside the quill and I could wiggle the drawbar and push it upwards, but it wouldn't pull out by hand. It should just be a bar with a thread on the end, right? Is this held in place with some collar/retainer?

I did a little homework before I went to look at the machine. As luck would have it, this was the one machine that Wells-Index did not have information about in their database. The girl on the phone did tell me that she has info on the model before and after, but not this one. I also got a quote for an R8 spindle regrind. It's like $500 which includes shipping.

Is it too far gone? There's that part in my head that says, "DO IT". But, I'm looking for a TOUGH machine away from my days of running the little Atlas horizontal mill.

I'm including pics and a quick video. Ignore the statement I make in the video, about not knowing what the "star" knob is used for. I have read that it allows you to adjust a stop position to prevent accidents with the powerfeed.

Table feed

That bottom shaft is essentially flopping around. It has a worm gear at the power feed engaging handle and it does spin when the powerfeed motor is running.

I could turn the quill power feed pulleys by hand, but no movement on the quill. The fine feed handle on the front spins freely. Probably something broke inside.