- Joined

- May 8, 2013

- Messages

- 33

8ntsane Good job on those adapter plates. I know it's no small trick getting those buggers parallel and flat with no "singing" chatter.

Ed Hoc

Very Nice work! That bolt action retractablr threading tool is very impressive.My not too fancy bolt action retractable threading tool. It works great and was easy to make...even for me. Also, my version of a great tangential lathe tool design by Lew Hartswick.

- - - Updated - - -

- - - Updated - - -

In response to a PM from Que requesting pics, and infro on a Tool Post Grinder for the AXA tool post. I used a boring bar holder that was a extra laying around. I bored it out to 1 inch ID, then used a slit saw acoss the side. Then drilled and tapped for a pinch bolt.

The hand piece is a Foredom unit, as is the motor. These hand pieces are cheap, very compact, and bearing are easy to change, and US made. Cable driven with remote motor. I use this type of hand piece, as I have many foredome products, and been very happy over the yrs. Good for light grinding jobs, and trueing up chuck jaws, what I mainly use it for.

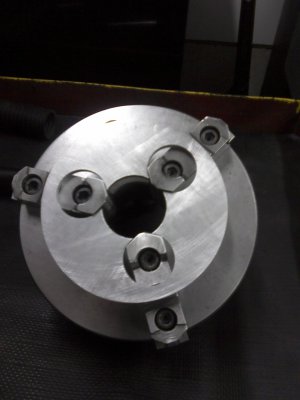

This is a 60 hole spindle indexer I drilled into my adapter plate on my 8 inch 4 jaw. The spring loaded spindle lock clamps to the outer way. Great for indexing bolt patterns, and not having to tear the setup down and move to the mill, a real time saver.

Whoops, these pics needed to be turned 90 degrees, just tilt your head left, its all good .lol

8ntsane-

You make me want to make all of these!! And such beautiful work!! Wow...

With the indexing chuck backplate- do you put something on the compound to drill or something? Or are you using a tool in a toolholder to make marks (like for a bolt pattern) while set up to make it easier to move to another machine?

Bernie