One question:

Where were the saw and blades manufactured?

Where were the saw and blades manufactured?

Yes, that might be the cause.One question:

Where were the saw and blades manufactured?

When I got my saw there was no down speed adjustment mounted to control it. I lower the frame and once it makes contact with the metal to be cut it has the weight of the frame. I just keep the guides close as to support the blade and keep it from bowing. Been doing it this way for over 20 years with no problems at all.I found with mine that hanging a 2' length of 1/2" chain on the tension knob speeds up the cutting on most stock with no ill affects. Have also used cutting oil without issues, though lately I've just been cutting dry. Still running the blade that came on it used, and after hundreds of cuts it still cuts well, other than missing a few teeth when I got it. Mike

No info on where the saw is manufactured but the Swedish manual(which I'm inclined to trust since it's from a reliable brand) states that it's living up to a whole bunch of different EU standards.One question:

Where were the saw and blades manufactured?

This saw has some kind of spring inside the hinge, so it's applying 0 weight onto whatever it's cutting.When I got my saw there was no down speed adjustment mounted to control it. I lower the frame and once it makes contact with the metal to be cut it has the weight of the frame. I just keep the guides close as to support the blade and keep it from bowing. Been doing it this way for over 20 years with no problems at all.

I have heard similar stories, where the small radius of the wheels will basically fatigue the metal faster than the teeth wears.There is place in the next town over from me who specialize in bandsaw blade of all shapes and sizes. The owner usualy drop my blades they make up for me off at my home. I told him about my small bandsaw also braking one blade after the other and I did all the adjustments I could and said to me that the problem lies with the small OD of the wheels,making the radius too small, that is on these small bandsaws. I tend to believe him. And guess what......just befor I saw this post,I broke yet another blade........again. I am so sick and tired of blades braking way before the teeth are worn. I did everything the OP posted and everything the members here suggested when I asked about the same problem a while back,but they keep on breaking. This is the one I have. A real cheapie

I understand what you were told, but I just can't agree. My money is on one of the wheels if not both is/are cocked. Broken blades were improperly annealed welds or too much material being ground off when smoothing the weld joint. Possibly FPM is too fastThere is place in the next town over from me who specialize in bandsaw blade of all shapes and sizes. The owner usualy drop my blades they make up for me off at my home. I told him about my small bandsaw also braking one blade after the other and I did all the adjustments I could and said to me that the problem lies with the small OD of the wheels,making the radius too small, that is on these small bandsaws. I tend to believe him. And guess what......just befor I saw this post,I broke yet another blade........again. I am so sick and tired of blades braking way before the teeth are worn. I did everything the OP posted and everything the members here suggested when I asked about the same problem a while back,but they keep on breaking. This is the one I have. A real cheapie

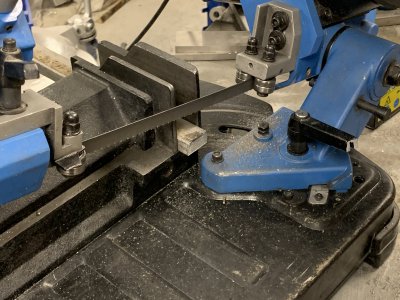

View attachment 435810

View attachment 435811

There is place in the next town over from me who specialize in bandsaw blade of all shapes and sizes. The owner usualy drop my blades they make up for me off at my home. I told him about my small bandsaw also braking one blade after the other and I did all the adjustments I could and said to me that the problem lies with the small OD of the wheels,making the radius too small, that is on these small bandsaws. I tend to believe him. And guess what......just befor I saw this post,I broke yet another blade........again. I am so sick and tired of blades braking way before the teeth are worn. I did everything the OP posted and everything the members here suggested when I asked about the same problem a while back,but they keep on breaking. This is the one I have. A real cheapie

View attachment 435810

View attachment 435811

Milwaukee, Porter Cable and the rest use 44 7/8"blades on 6" diameter wheels on there portable saws with no problem. If the blades you are using are an 1/8" either way ( 45 or 44 3/4") that's a problem.I have heard similar stories, where the small radius of the wheels will basically fatigue the metal faster than the teeth wears.

Maybe one day when I have that magical thing called "free time" I'll build one with larger wheels.