-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small Bench Top Hydraulic Press (10 ton X 8")

- Category Fabrication Projects

- Category Machine Build Projects

- Category Specialty Builds

- Thread starter bretthl

- Start date

nice! that'll still be pretty handy I'm sure. I'd suggest tying the bottom of the legs together somehow, in addition to the "table" which I'm guessing can be raised from its current position. Even some 1/4" or 3/8" plate using the feet bolts would be helpful.

I fixed my internet issue and am back.

The ram is Chinese, all I could find that would not break the bank. I don't know much about hydraulics but the 2-1/4"-14 tpi thread on the tube looked ideal for mounting. The thread on the ram is 1-1/4" NPT and I have a forged coupling that I will work into an adapter.

I used the lathe face plate to hold for boring and cutting the threads for mounting the ram:

The mounting plate is 1/2" thick A36 and I got a very snug thread engagement.

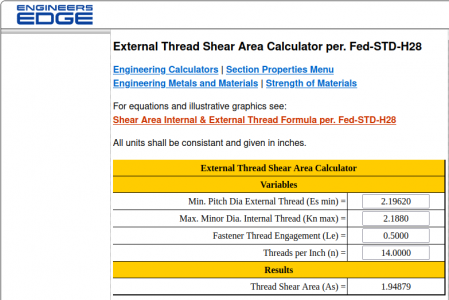

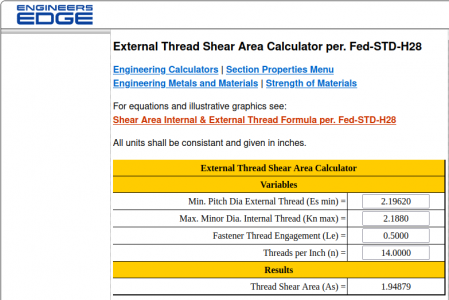

I ran the thread strip numbers on the ram mounting threads as follows:

A36 has an approximate shear value of (36,000 psi)(0.58) = 21 Ksi.

So the safety factor at full load should be around (21 Ksi)(1.9 sqin) / (10 ton)(2000 lb/ton) = 2.0

Here is a side view. I used grade 8 bolts and avoided welding all but the base support.

.

.

The ram is Chinese, all I could find that would not break the bank. I don't know much about hydraulics but the 2-1/4"-14 tpi thread on the tube looked ideal for mounting. The thread on the ram is 1-1/4" NPT and I have a forged coupling that I will work into an adapter.

I used the lathe face plate to hold for boring and cutting the threads for mounting the ram:

The mounting plate is 1/2" thick A36 and I got a very snug thread engagement.

I ran the thread strip numbers on the ram mounting threads as follows:

A36 has an approximate shear value of (36,000 psi)(0.58) = 21 Ksi.

So the safety factor at full load should be around (21 Ksi)(1.9 sqin) / (10 ton)(2000 lb/ton) = 2.0

Here is a side view. I used grade 8 bolts and avoided welding all but the base support.

.

.Looks good. Smaller than my benchtop unit. Mine is only for 2 ton. I like what you did up top... but I think your crossbars are a little light on the bottom. And not being joined together may cause them to bow out.... I don't understand you used heavy construction on the top.. C channel, what appears to be 3/8 plate, double grade 8 on the c channel... and then a light crossbar... ??????????????

Looks good. Smaller than my benchtop unit. Mine is only for 2 ton. I like what you did up top... but I think your crossbars are a little light on the bottom. And not being joined together may cause them to bow out.... I don't understand you used heavy construction on the top.. C channel, what appears to be 3/8 plate, double grade 8 on the c channel... and then a light crossbar... ??????????????

The cross bars are 2" x 1/2" and I am working on the table which will be 1/2" thick. All new to me so I may be making adjustments.

I like Matt's suggestion, a 3/8 plate pinned/bolted to the bottom to keep everything together.

8” is window height, width or depth? Sorry if I’m being dense on the nomenclature

Sent from my iPhone using Tapatalk