-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

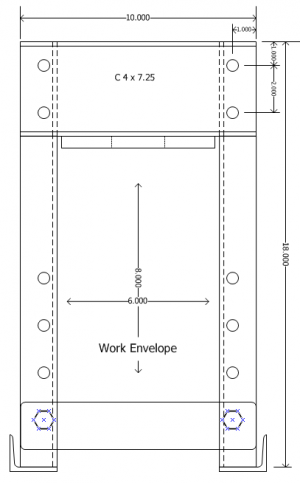

Small Bench Top Hydraulic Press (10 ton X 8")

- Category Fabrication Projects

- Category Machine Build Projects

- Category Specialty Builds

- Thread starter bretthl

- Start date

I toyed with the idea of a pneumatic over hydraulic foot pump but decided that would be overkill for my needs. I found a good deal on a new Enerpac P-202 manual pump on ebay (https://www.ebay.com/itm/283805583625) and also purchased an Enerpac hose with pressure gauge from the same seller. The P-202 gives 0.221 in^3 / stroke in low pressure mode and 0.055 in^3 in high pressure mode.Thats exeactly what I want next a forging press. What is the speed you'll have with this set up?

The ram is a Jackco Model 684 (8" stroke, 10 ton, SPRING RETURN). The fluid capacity is 18 in^3. I found this also on ebay (https://www.ebay.com/itm/371383947709). Jackco publishes detailed specifications on their rams (most others don't). This one has a fluid capacity of 19.7 in^3, an effective ram area of 2.462 in^2 and a max operating pressure of 8950 psi. The effective ram area times the hydraulic fluid pressure gives the force that the ram is applying. I need to convert pressure to ram force for load testing.I have a similar frame with no hydraulics, where did you get the ram?

To completely displace the ram (8") will require about 90 strokes in low pressure mode. I better keep a stack of shims handy!

8” is window height, width or depth? Sorry if I’m being dense on the nomenclature

Sent from my iPhone using Tapatalk

Yep, no short cuts allowed there.Enerpac makes 2 speed pumps that are not much more expensive. I wish I had gone that route. You may already know this but most hydraulic fittings are not rated to go up to 10K PSI.

Robert

Looks good. And not a weld to be found. Did you make plans for this? Can they be posted?

Will be watching this- definitely would like to learn more about your project, I could use a good sturdy, small press. Good work!

its nice, but the bottom support of the press the holes should at least be on the bottom, so you have more meat on top of the screws. Pressure is down, so you want as much support as you can get, those holes in that orientation are near the top of the bars..

I also would put some caps on the bottom tubes, if something falls in, it will be a bear to get out.

I also would put some caps on the bottom tubes, if something falls in, it will be a bear to get out.