- Joined

- Apr 1, 2013

- Messages

- 1,142

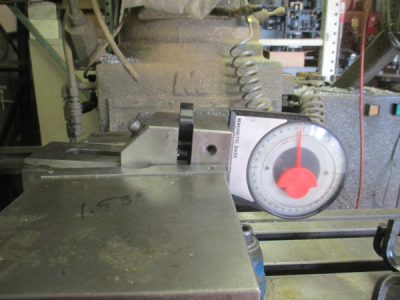

I plan to Machinist from a piece of half by half Square stock making a few of them at the same time doing all machine work then cutting to size. The question is what would be a good way to machine the flat bottom V in the middle. Have not had a chance to measure the angles but was considering flattening the end of a countersink Machining the slot through the center Square and then gently over several passes cutting the inside angle.

I understand countersunk not really designed to cut sideways but was thinking for this later Cuts I may be able to get away with it. Trying to avoid repositioning the part multiple times or tilting ahead of the mill.

The part is part of the clamping mechanism to hold a scope to a pellet rifle.

I understand countersunk not really designed to cut sideways but was thinking for this later Cuts I may be able to get away with it. Trying to avoid repositioning the part multiple times or tilting ahead of the mill.

The part is part of the clamping mechanism to hold a scope to a pellet rifle.